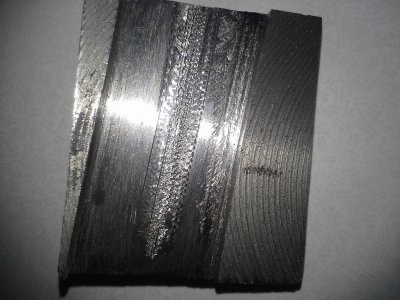

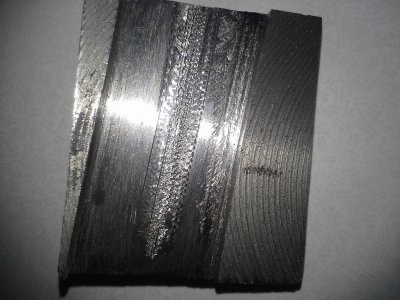

Recently, I was in the TechShop, which is a shared machine membership facility. Usually, there are some end mills in the mill box. They are often not in very good shape, but they do work a little bit. This time, there were only two. One had the end snapped off. It would still work for side milling. The other just had a burned up end. I thought it might be fun to try to see if I could sharpen the end mill by hand on the grinder. There was no dresser available, so the right edge of the wheel was a little rounded. The primary relief was ground at about 5 degrees with a slight angle in towards the center to form a dish. The resulting grind did cut, but it left a furrow down the center-line of the slot. Is this caused by not gashing the end mill correctly. These are kind of junk community end mills, so there is nothing much lost if they are goofed up a bit. By the way, it was much improved by the grinding session.