Still no test cut, but getting closer.

Here's a pic of the Compact 8 on the bench. The control panel is temporarily mounted a little high so I can still access the headstock adjustment hardware. The wood scraps between the aluminum tubes are there to prevent anything from falling into the back of the control panel.

Although the little square steel adjuster bars mounted below the tabletop worked out well, I did notice that the carriage handwheel is a little too close to the work surface, especially with the trays in place. The small steel mounting pads at the surface are 3/8 x 2 x 4-1/4 inch. Might be better to pad them up a little more, maybe with some square tubing (?).

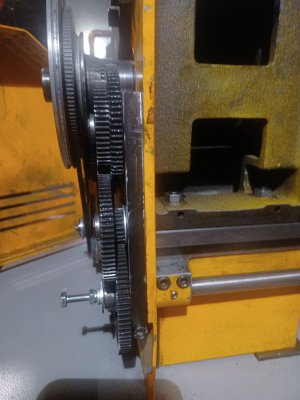

The change gear setup was just a bit wonky.

The headstock hangs over the end of the bed about 1/8 inch. That limits the grip of the banjo bar onto the boss holding the leadscrew in place. I ended up padding out the little change gear axles with fender washers in order to hold alignment at the gear on the spindle. It looks like I could also use some sort of key slotted bushing to help maintain gear position of the last gear (on the leadscrew itself). Presently, the only thing stopping the gear from sliding towards the right is where the side of the teeth catch against the washer on the side of the intermediate gear.

Not pretty, but it works.

TomKro

Here's a pic of the Compact 8 on the bench. The control panel is temporarily mounted a little high so I can still access the headstock adjustment hardware. The wood scraps between the aluminum tubes are there to prevent anything from falling into the back of the control panel.

Although the little square steel adjuster bars mounted below the tabletop worked out well, I did notice that the carriage handwheel is a little too close to the work surface, especially with the trays in place. The small steel mounting pads at the surface are 3/8 x 2 x 4-1/4 inch. Might be better to pad them up a little more, maybe with some square tubing (?).

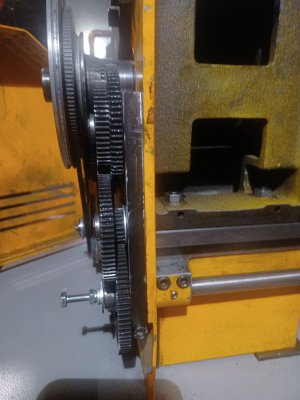

The change gear setup was just a bit wonky.

The headstock hangs over the end of the bed about 1/8 inch. That limits the grip of the banjo bar onto the boss holding the leadscrew in place. I ended up padding out the little change gear axles with fender washers in order to hold alignment at the gear on the spindle. It looks like I could also use some sort of key slotted bushing to help maintain gear position of the last gear (on the leadscrew itself). Presently, the only thing stopping the gear from sliding towards the right is where the side of the teeth catch against the washer on the side of the intermediate gear.

Not pretty, but it works.

TomKro