- Joined

- Mar 31, 2014

- Messages

- 607

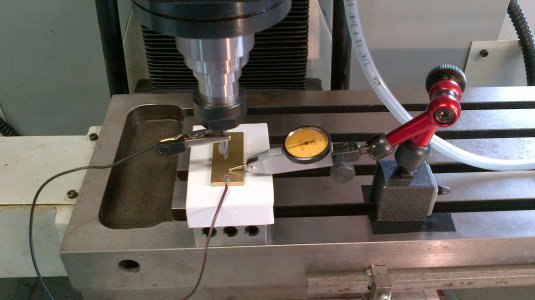

This is just an update on my progress with using a touch plate to set the Z height on my CNC using Mach3.

I wired this using the wiring diagram from post #1 and the info from post #6 "How to setup touch plate.doc" posted by acourtjester.

It's working great through repeated testing and I'm very happy with the setup, I did overlook one thing even though I read the document repeatedly I overlooked the fact that it states to use a piece of "PCB material" and I soon found out why, the plate can not ground out or the touch off plate will not work properly, I used a piece of brass plate which worked great when used off pieces of foam for testing but as soon as I tried it off of a piece of aluminum I soon realized my error, a small piece of screen protector on the bottom of my brass plate fixed this issue.

There is one thing though that anyone considering a setup such as this, is the fact that to high of a feed rate will cause the tool to travel on even after the signal is detected.

The VB Code for Auto Tool Zero has a value of 20 for a feed rate which was a little fast for my comfort, so I slowed it down to 15 but I was still concerned that the tool may travel after a signal was detected.

My testing setup is admittedly crude but the results where very consistent and repeatable throughout a couple of hours of testing.

Feed rate 15 --> Over run .0019

Feed rate 10 --> Over run .0010

Feed rate 05 --> Over run .0003

Feed rate 02 --> Over run .0001

Regardless of the tool over run results using the 4 different feed rates the tool height constantly finished at the exact same height as near as I could detect with my .0001 indicator.

Just something to think about if your considering a setup like this, I'll be making a new touch off plate that will allow some over run of the tool.

I wired this using the wiring diagram from post #1 and the info from post #6 "How to setup touch plate.doc" posted by acourtjester.

It's working great through repeated testing and I'm very happy with the setup, I did overlook one thing even though I read the document repeatedly I overlooked the fact that it states to use a piece of "PCB material" and I soon found out why, the plate can not ground out or the touch off plate will not work properly, I used a piece of brass plate which worked great when used off pieces of foam for testing but as soon as I tried it off of a piece of aluminum I soon realized my error, a small piece of screen protector on the bottom of my brass plate fixed this issue.

There is one thing though that anyone considering a setup such as this, is the fact that to high of a feed rate will cause the tool to travel on even after the signal is detected.

The VB Code for Auto Tool Zero has a value of 20 for a feed rate which was a little fast for my comfort, so I slowed it down to 15 but I was still concerned that the tool may travel after a signal was detected.

My testing setup is admittedly crude but the results where very consistent and repeatable throughout a couple of hours of testing.

Feed rate 15 --> Over run .0019

Feed rate 10 --> Over run .0010

Feed rate 05 --> Over run .0003

Feed rate 02 --> Over run .0001

Regardless of the tool over run results using the 4 different feed rates the tool height constantly finished at the exact same height as near as I could detect with my .0001 indicator.

Just something to think about if your considering a setup like this, I'll be making a new touch off plate that will allow some over run of the tool.