- Joined

- Jun 12, 2014

- Messages

- 401

Covered in cosmoline...and black widow egg sacks?! What are those little white spheres?

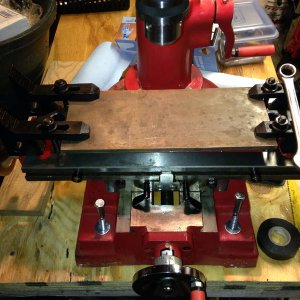

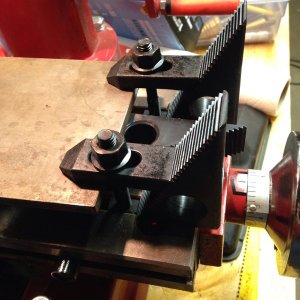

. If you have room, a coupling nut instead if the normal nut on your drawbar is better as after a few whacks, the mushroom makes it hard to fit a spanner whereas with a longer nut you can use the lower part until you need to grind it back. That fine feed looks like a good plan and if you get too much play, a gas strut to hold the head up is one idea. Regarding the clamping set, can't you mill down the tee nuts to fit your table or make/buy some and use all thread for the bolts. They do'nt have to be super strong in this table. I use coach bolts with ground down heads sometimes. Waiting for your 4 axis CNC conversion

. If you have room, a coupling nut instead if the normal nut on your drawbar is better as after a few whacks, the mushroom makes it hard to fit a spanner whereas with a longer nut you can use the lower part until you need to grind it back. That fine feed looks like a good plan and if you get too much play, a gas strut to hold the head up is one idea. Regarding the clamping set, can't you mill down the tee nuts to fit your table or make/buy some and use all thread for the bolts. They do'nt have to be super strong in this table. I use coach bolts with ground down heads sometimes. Waiting for your 4 axis CNC conversion .

.