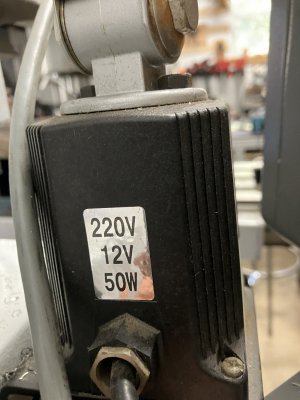

I had been looking for a knee mill for over a year on FBM, CL, and industrial auctions; almost every day, twice a day. A few minutes after the heartbreak of being the second best bidder on my fourth Bridgeport (4 times the 2nd best bidder), this PM935 popped up on FB 500 miles away. I had almost pulled the trigger several times on an new 935 so I was very familiar with the quality and value. After "waiting" to think it over on several FBM and CL machines and loosing them in the matter of hours, I jumped right in with a full price offer, which I felt was very fair. About 10 years old, barely used by a hobbyist, with a PM vise, a PM installed VFD, aftermarket DRO, a box of unused USA end mills, collet and rack, fly cutters, and a box of parallels that only had 2 sets showing use. The add went up and I was the first person to respond at 14 minutes. The kind seller offered to hold it for 2 weeks despite plenty of other local buyers. Seller loaded it with me with an engine hoist and 1100 miles and 5k poorer, I was in business. Wonderful seller and wonderful drive.

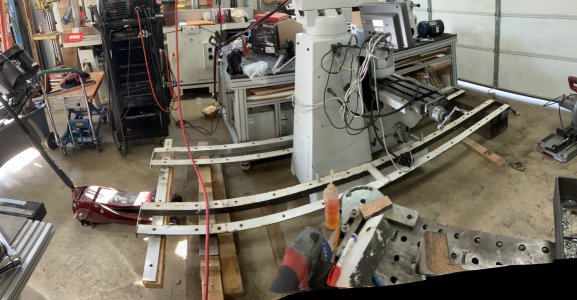

Step1: Getting it off the trailer was a different story and I thought posting this might be helpful if anyone else wants to give this a try. Because of the angles and heights involved, another engine hoist was no longer an option. When I first loaded the mill, I dropped it onto two full dimension 2x12"x 6'. To get it out, my dad and I jack-knifed the trailer into my shop (20 foot urban alley), ratchet strapped the mill onto the skids and wedged it between blocking, bolted an anchor into a 24"x24" footing, and used a come along to drag it out of the trailer, with ratchet straps on the backside to keep it somewhat supported. I did the next part solo, slow and deliberately.

Step 2: Next tricky part was getting it in the air without a gantry or engine hoist. I had some free 1/4"x2x2.5 angle laying around the shop. I finished through-tapping the 3/4" mounting hose on the PM's base, ran 3/4" all thread into the base, and rested the angle within drillpress-precise holes over the allthread. I then used blocks and a floor jack to get it up in the air for a few days while I could build my best conglomeration of the David Best & Firestopper mobile base that I could, sans using a brake as shown in this thread : https://www.hobby-machinist.com/threads/mobile-base-for-a-mill.53405/. The base gets me about 3" over stock height, with all the holes tapped and the M14 leveling feet going through 1/4" tubing plus an 1" of extra matereial I turned on my lathe and welded under the 1/4". I was going to have the all thread go straight into tapped 3/4" holes on the base, but I didn't want to test my luck on my measuring abilities, so it runs through 7/8" holes with lock nuts underneath the base.

Thanks everyone for your support over the last year. A special thanks to Firestopper for all the compliments I have received from friends and family on my stand, and to Mr. Best for prepurchase support and excellent documentation/write-ups on the PM935 and the design difficulties of the combined wood/metalwork in a small urban shop.

Step1: Getting it off the trailer was a different story and I thought posting this might be helpful if anyone else wants to give this a try. Because of the angles and heights involved, another engine hoist was no longer an option. When I first loaded the mill, I dropped it onto two full dimension 2x12"x 6'. To get it out, my dad and I jack-knifed the trailer into my shop (20 foot urban alley), ratchet strapped the mill onto the skids and wedged it between blocking, bolted an anchor into a 24"x24" footing, and used a come along to drag it out of the trailer, with ratchet straps on the backside to keep it somewhat supported. I did the next part solo, slow and deliberately.

Step 2: Next tricky part was getting it in the air without a gantry or engine hoist. I had some free 1/4"x2x2.5 angle laying around the shop. I finished through-tapping the 3/4" mounting hose on the PM's base, ran 3/4" all thread into the base, and rested the angle within drillpress-precise holes over the allthread. I then used blocks and a floor jack to get it up in the air for a few days while I could build my best conglomeration of the David Best & Firestopper mobile base that I could, sans using a brake as shown in this thread : https://www.hobby-machinist.com/threads/mobile-base-for-a-mill.53405/. The base gets me about 3" over stock height, with all the holes tapped and the M14 leveling feet going through 1/4" tubing plus an 1" of extra matereial I turned on my lathe and welded under the 1/4". I was going to have the all thread go straight into tapped 3/4" holes on the base, but I didn't want to test my luck on my measuring abilities, so it runs through 7/8" holes with lock nuts underneath the base.

Thanks everyone for your support over the last year. A special thanks to Firestopper for all the compliments I have received from friends and family on my stand, and to Mr. Best for prepurchase support and excellent documentation/write-ups on the PM935 and the design difficulties of the combined wood/metalwork in a small urban shop.