When I had my Shooting Star DRO on my RF-45 mill, I put the encoder assembly on the front of table (pics). When I changed to a Newall system I put it on the back of table & prefer it there. It has a heavy aluminum channel protecting the encoder & I have a rubber apron from table to dovetail pillar that keeps swarf from getting back there.

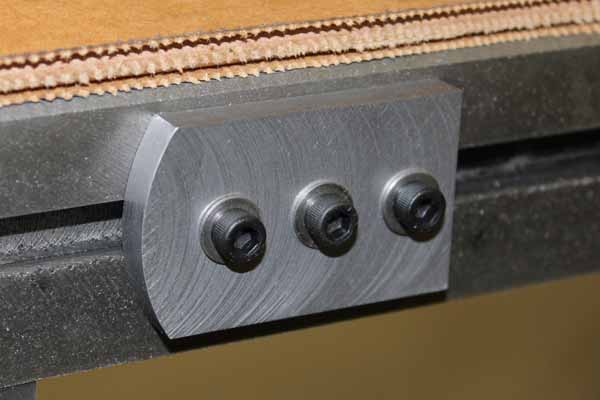

So having done it both ways I prefer a cleaner front table edge. My table clamp handles are in the same vicinity. I also made better X-direction stops which are much more positive than the stock 'washers'. However they are wider so would have interfered with encoder. I also replaced the cheesy stock center stop with a meatier machined stop. I also have a power feed but don't use the limit stop. A bit of risk yes, but the front edge only has so much real estate to accommodate all this stuff so you have to decide what's functionally important to you.

So having done it both ways I prefer a cleaner front table edge. My table clamp handles are in the same vicinity. I also made better X-direction stops which are much more positive than the stock 'washers'. However they are wider so would have interfered with encoder. I also replaced the cheesy stock center stop with a meatier machined stop. I also have a power feed but don't use the limit stop. A bit of risk yes, but the front edge only has so much real estate to accommodate all this stuff so you have to decide what's functionally important to you.