Hello,

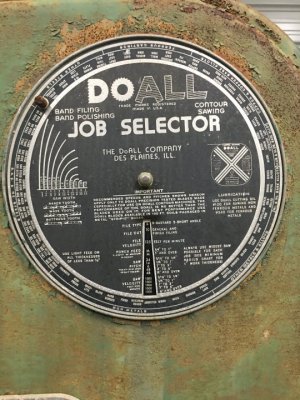

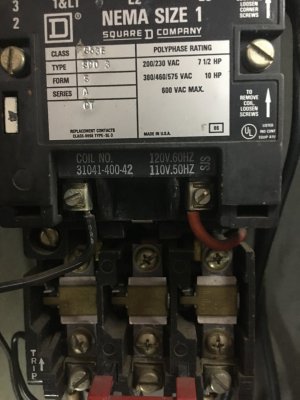

I recently purchased a DoAll MP-20 which appears for the most part in good condition, especially considering it was under a tarp on a trailer under a carport for several years. I know I have some cleaning on my hands but the area that concerns me is the transformer. I've attached some pics of the machine. Anyone know where I can get that transformer repaired, if it is necessary, or where I can get a new/good used one if it is beyond repair. I'm guessing the transformer takes the incoming 460V 3phase the machine was wired for and lowers that to 120V single phase or am I way off on that? There were some bird nests in there so I was at least planning on removing the transformer and making sure there aren't any bare wires which would make touching the machine shocking. The motor is capable of being wired 240V 3phase which was my plan. Any help on this would be greatly appreciated. Thanks for your help,

TwinDad

I recently purchased a DoAll MP-20 which appears for the most part in good condition, especially considering it was under a tarp on a trailer under a carport for several years. I know I have some cleaning on my hands but the area that concerns me is the transformer. I've attached some pics of the machine. Anyone know where I can get that transformer repaired, if it is necessary, or where I can get a new/good used one if it is beyond repair. I'm guessing the transformer takes the incoming 460V 3phase the machine was wired for and lowers that to 120V single phase or am I way off on that? There were some bird nests in there so I was at least planning on removing the transformer and making sure there aren't any bare wires which would make touching the machine shocking. The motor is capable of being wired 240V 3phase which was my plan. Any help on this would be greatly appreciated. Thanks for your help,

TwinDad