-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY De-Mag!

- Thread starter MERLIncMan

- Start date

- Joined

- Feb 13, 2017

- Messages

- 2,138

So am I reading you correctly that a soldering gun can double as a demagnetizer?

Rather than a conventional tip, I use a coil of 6AWG copper.

DIY Tool Demagnetizer

A few days ago, I commented in another thread about using a soldering gun for demagnetizing tools, parts, etc. For a long time, I have used 10AWG copper wire for making my own soldering tips. At one point, I reshaped one of the tips into a circle and it worked very well for demagnetizing screw...www.hobby-machinist.com

To properly use a demagnetizer, you insert to object to be demagnetized and slowly withdraw it from the loop before shutting off the current. If you want to magnetize an object, insert it into the loop and power the gun on and off. If you hit it just right, the current will be at a maximum and the object will be magnetized. Pull it out and try to pick up some iron. If not satisfied, try it again.

EDIT Although it is possible to magnitize aqn object in this manner, simply pulling a strong magmet over an object works better. There must be a fair amount of carbon in the steel to magnetize it.

Since I work with small parts and tools, most times a regular tip on the D-550 works for me. On rare occasions, I need to DeMag something larger than the tip will accept. Like RJSakowski,, but with AWG-10 wire, I make a loop. Usually with a couple or three turns to intensify the field.

Magnetism is closely related to electricity. I could lecture for hours on the subject. That's how electricity is produced. . . A soldering "gun" consists of a very high(?) reduction transformer that produces a very low voltage. Just a volt or two. There are several(!) web sites where a light duty welder is produced from microwave oven transformers. The same process is the resultant of a soldering iron. The only difference is a soldering iron uses a "closed loop" rather than striking an arc.

As the voltage is reduced, current is increased. A soldering iron works because the large brackets and relatively small tip cause the tip to get hot from the high current flow. The same effect can be replicated with a welder. Shorting the output through a small wire will produce the same effect. The welder must be set to a relatively low "current" and the wire must be balanced in size to the rated current. Numerous coils may be necessary for the demagnatizing to be effective. These coils may be made with the welder's cable, so a quite large chunk of iron can be demagnitized.

To "magnetize" a piece of iron, a D-C welder will work better, as an A-C device is reversing 120 times a second. And, of course, D-C must never be applied to a transformer. Hitting the peak voltage is a hit or miss proposition, at best. The simplist method is to simply use a bar magnet and stroke the iron repeatedly. For very large items, you'll need a D-C welder or the like.

I have a D-C welder that I finagled from a Lincoln "Buzz Box", some 225 Amps max. The diodes are on the secondary of the transformer and are enormous. Each one about the size of my fist, rated at 500 Amps and a kilovolt. A generator would probably work better, but the diodes were salvage. The only cost was a piece of copper pipe for buss bars. And a lot of time.

As I said earlier, I could lecture for hours on the subject. This missive is becoming such a lecture, I've talked far too long. I cover the subject lightly in a document on my personal web site;

http://www.hudsontelcom.com/uploads/ShopElex.pdf

It does not get too serious beyond a basic introduction. But it may be enough if the interest is there. The pointers in the bibliography are mostly for electrical subjects, but since the two are so closly related, each touches further on the subject.

Bill Hudson

.

- Joined

- May 3, 2017

- Messages

- 2,028

Thanks, Bill.Since I work with small parts and tools, most times a regular tip on the D-550 works for me. On rare occasions, I need to DeMag something larger than the tip will accept. Like RJSakowski,, but with AWG-10 wire, I make a loop. Usually with a couple or three turns to intensify the field.

Magnetism is closely related to electricity. I could lecture for hours on the subject. That's how electricity is produced. . . A soldering "gun" consists of a very high(?) reduction transformer that produces a very low voltage. Just a volt or two. There are several(!) web sites where a light duty welder is produced from microwave oven transformers. The same process is the resultant of a soldering iron. The only difference is a soldering iron uses a "closed loop" rather than striking an arc.

As the voltage is reduced, current is increased. A soldering iron works because the large brackets and relatively small tip cause the tip to get hot from the high current flow. The same effect can be replicated with a welder. Shorting the output through a small wire will produce the same effect. The welder must be set to a relatively low "current" and the wire must be balanced in size to the rated current. Numerous coils may be necessary for the demagnatizing to be effective. These coils may be made with the welder's cable, so a quite large chunk of iron can be demagnitized.

To "magnetize" a piece of iron, a D-C welder will work better, as an A-C device is reversing 120 times a second. And, of course, D-C must never be applied to a transformer. Hitting the peak voltage is a hit or miss proposition, at best. The simplist method is to simply use a bar magnet and stroke the iron repeatedly. For very large items, you'll need a D-C welder or the like.

I have a D-C welder that I finagled from a Lincoln "Buzz Box", some 225 Amps max. The diodes are on the secondary of the transformer and are enormous. Each one about the size of my fist, rated at 500 Amps and a kilovolt. A generator would probably work better, but the diodes were salvage. The only cost was a piece of copper pipe for buss bars. And a lot of time.

As I said earlier, I could lecture for hours on the subject. This missive is becoming such a lecture, I've talked far too long. I cover the subject lightly in a document on my personal web site;

http://www.hudsontelcom.com/uploads/ShopElex.pdf

It does not get too serious beyond a basic introduction. But it may be enough if the interest is there. The pointers in the bibliography are mostly for electrical subjects, but since the two are so closly related, each touches further on the subject.

Bill Hudson

.

Great info.

- Joined

- Jun 26, 2018

- Messages

- 1,733

So if I'm following...you removed the blades, but regardless, if you put a magnetized (screwdriver) near a set of beard trimers, you would demagnetize the screwdriver?

- Joined

- Feb 13, 2017

- Messages

- 2,138

De-magnetizing screwdrivers is my most common usage. I stick the screwdriver between the brackets or inside the tip. Powering on the soldering iron and slowly withdrawing the screwdriver until it is a foot or two away from the soldering iron, then powering down (releasing the switch) the soldering iron. Sometimes two or three passes are necessary when the chemistry of the iron in the tool makes it more or less magnetic.

This only works on "induction" soldering irons. Many soldering irons use a heater internally. They take a couple or three minutes to heat up. An induction iron heats up in a couple of seconds, and cools almost as quickly. A Weller 8200 is rated at 100/140 watts. This is not the actual wattage used, rather a "heat equivilent" to a heater type.

Shock will remove a large portion of magnetism in many tools. And the shock also removes loose particles through inertia. My usage on the (wooden) bench is nowhere near the machines. While the soldering iron is on a bracket right at hand. My concern is steel screws and the like. Brass is nonmagnetic, but much "brass" hardware is actually brass plated steel. Good quality stainless steel is also non-magnetic, but lesser quality stuff is somewhat magnetic. All of this is at play on my bench.

.

.

This only works on "induction" soldering irons. Many soldering irons use a heater internally. They take a couple or three minutes to heat up. An induction iron heats up in a couple of seconds, and cools almost as quickly. A Weller 8200 is rated at 100/140 watts. This is not the actual wattage used, rather a "heat equivilent" to a heater type.

Shock will remove a large portion of magnetism in many tools. And the shock also removes loose particles through inertia. My usage on the (wooden) bench is nowhere near the machines. While the soldering iron is on a bracket right at hand. My concern is steel screws and the like. Brass is nonmagnetic, but much "brass" hardware is actually brass plated steel. Good quality stainless steel is also non-magnetic, but lesser quality stuff is somewhat magnetic. All of this is at play on my bench.

.

.

- Joined

- Jan 7, 2016

- Messages

- 3,380

- Joined

- Feb 13, 2017

- Messages

- 2,138

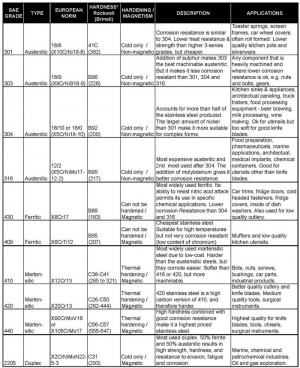

My comments about stainless steel were not intended as a judgement of value, but rather the metalurgical capacity of the steel. The term greater or lesser "quality" is referring to the metalurgical content, not the "value". I don't get hung up on semantics or charts, I use whatever is appropriate to a given situation, be it stainless, carbon steel, aluminium, or plastics. Each of which has numerous characteristics making it suitable or unsuitable for a given application. For example, stainless of any quality is not suitable for a motor. Nor is brass (or bronze) suitable for an electromagnet. Except, perhaps, as an alternative conductor to copper.

In my younger days(Ca.1966), when automotive radios had vacuum tubes, there was a "vibrator" that allowed the D-C of the electrical system to be converted to A-C so it could be applied to a transformer. In later years, I worked on (tubes again) process control equipment that used a vibrator for some esoteric reason. It used 120 VAC so wasn't related to the power supply. It was called a "chopper" in that application, but a vibrator is a vibrator is a vibrator. Or not. . .

Funny how "semantics" have altered over just 40 years. The "quality" now is taken as "value", where to old folks it has a wholey differnt meaning. I guess my 1945 issue of Webster's is just a door stop now.

.

In my younger days(Ca.1966), when automotive radios had vacuum tubes, there was a "vibrator" that allowed the D-C of the electrical system to be converted to A-C so it could be applied to a transformer. In later years, I worked on (tubes again) process control equipment that used a vibrator for some esoteric reason. It used 120 VAC so wasn't related to the power supply. It was called a "chopper" in that application, but a vibrator is a vibrator is a vibrator. Or not. . .

Funny how "semantics" have altered over just 40 years. The "quality" now is taken as "value", where to old folks it has a wholey differnt meaning. I guess my 1945 issue of Webster's is just a door stop now.

.