Hello,

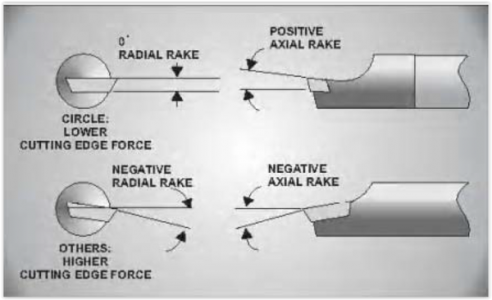

i would like to make myself a few boring bars for using them with my chinesium boring head in the mill but I'm not sure about the rake angle.

Here is what I have so far:

Inserts I have and want to use: CCMT060204 and TCMT110204 (both have 7° clearance angle)

Material for the bars: 1.2210 silver steel or drill rod, 12 mm diameter h8.

They will be used for very light work (600 watt Sieg mill) with 20xx class aluminum. I will use them only very few times during the next years, therefor I can't justify buying one or two. I did not find any information about insert holders for boring heads, usually I just copy my carbide holders from the ISO nomenclature depending on what I want to use them for. For external lathe tool holders, they came out good enough for what I want them to do.

I would be thankful if someone could point me in the right direction.

Short and simple: What is the commonly used rake angle on a general purpose boring bar to be used in a boring head?

i would like to make myself a few boring bars for using them with my chinesium boring head in the mill but I'm not sure about the rake angle.

Here is what I have so far:

Inserts I have and want to use: CCMT060204 and TCMT110204 (both have 7° clearance angle)

Material for the bars: 1.2210 silver steel or drill rod, 12 mm diameter h8.

They will be used for very light work (600 watt Sieg mill) with 20xx class aluminum. I will use them only very few times during the next years, therefor I can't justify buying one or two. I did not find any information about insert holders for boring heads, usually I just copy my carbide holders from the ISO nomenclature depending on what I want to use them for. For external lathe tool holders, they came out good enough for what I want them to do.

I would be thankful if someone could point me in the right direction.

Short and simple: What is the commonly used rake angle on a general purpose boring bar to be used in a boring head?