I had a chance today to fine tune the operation and play with it a bit. I also have it integrated in to my software so it can be controlled manually on the screen or under G-code control. Delivery Rate is controlled with a mouse click on a slider bar. Flow can be controlled from about 1 drop per 10 seconds to a steady stream with very fine adjustment available over the entire range. This could also be done manually using a small DC gear motor and a PWM controller, available cheap from FleaBay.

How it works

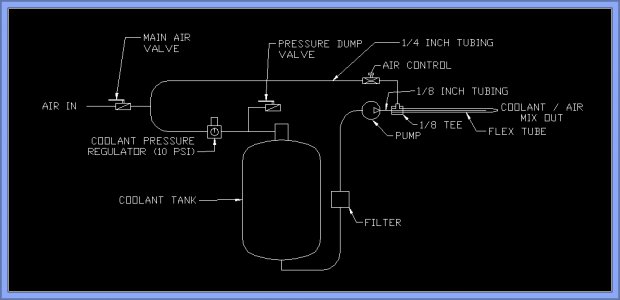

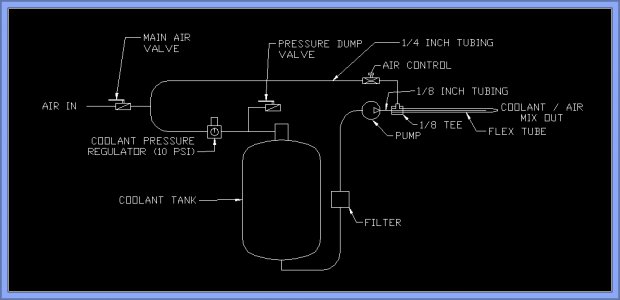

Here is a drawing of the major components and connections.

Because the original system used air pressure to dispense the fluid, I didn’t bother to change tanks. Since the pressure tank is sealed, it needs a vent so I am just pressurizing it to 10 PSI since the hardware is already installed. The new system could operate without the pressure tank, in fact you could just drop the intake hose to the pump into a bucket of coolant and the system would work fine.

In the drawing it shows manual valves to turn the air on and dump air from the tank, where in this case I am using a solenoid valve on the main air and a quick exhaust valve to dump the air off of the tank any time the solenoid is turned off.

The tank is a 20 lb sand blaster tank is from HF the rest of the components are available from many vendors. Small peristaltic pumps are available on FleaBay, or it’s a fun project to build one. If you haven’t read the first post in this thread, you might want to, it explains why I went this way.

http://www.hobby-machinist.com/threads/digital-mist-coolant-pump.40405/

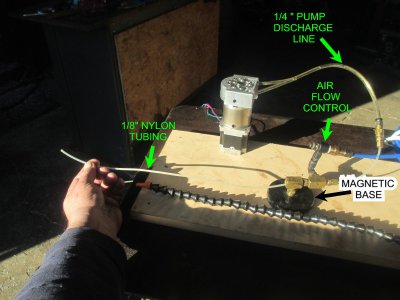

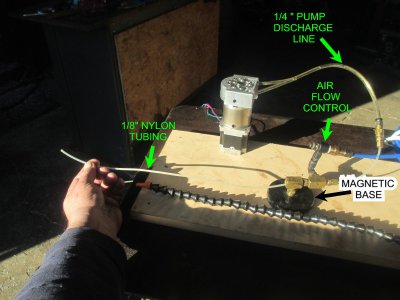

Here are the flow end components:

And the working end showing the relative length of the 1/8 inch nylon tube

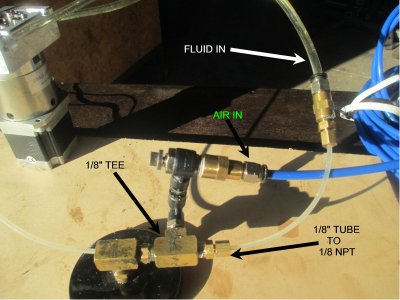

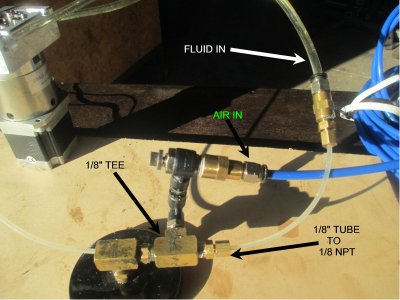

And a close up of the air plumbing. In order to get the 1/8 inch tube through the compression fitting, I had to run a 1/8 drill through it to open it up a bit. Didn’t seem to hurt the compression at all. I was mixing the fluid and air at the Tee, but I found it works better if you extend the nylon tube down the flex tube to near the end.

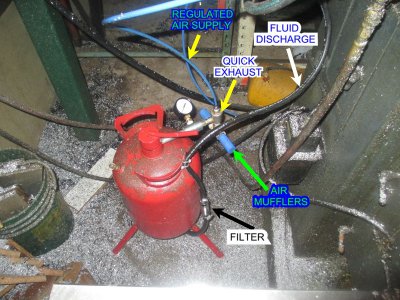

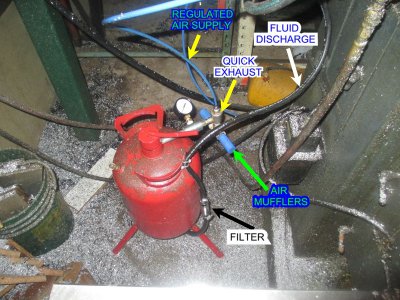

And installed on the mill (Tomorrow is clean up day

)

The coolant tank, it holds about 3.5 gallons

The solenoid valve and tank pressure regulator

The pump in it’s new home on top of the ram. The ram on this mill has a nice wide flat top and sides, lot’s room to mount stuff. (The air cylinder above the pump is the quill counterbalance cylinder.)

The front view

It’s really hard to get a picture of flowing droplets but here it is at about 10%

and at about 50% It puts out a nice micro droplet spray, but no fog.

‘

.