Software: UCCNCWhat controller are you running?

Controller: UC400ETH

BOB: PMDX 126 w/107 0-10v spindle board

EDIT - don't go searching Ebay and snapping up all the drives I just discovered!Gave the Copley a quick look over. Nice drive. It can do BLDC motors?

The XTL (and some others in the Xenus line) can do halls, differential encoder w/ halls, and diff encoder w/o halls.

The XTL-/S model can do analog encoder or analog halls /digital encoder

the XTL-/R model can do resolvers

Control signals: analog 0-10v, pwm, step/dir, external encoder for gearing/camming, CANopen, ASCII

Also has a secondary input for a load encoder (dual-loop)

buy a finished Tormach spindle cartridge rated for 10K.

Or a 12k version. Tormach is chinese after all..

https://www.aliexpress.com/item/323...chweb0_0,searchweb201602_4,searchweb201603_55

get my hands on a RF45 sized mill that I've been stalking.

Um...

https://cleveland.craigslist.org/tls/d/euclid-cnc-vertical-mill/7045473138.html

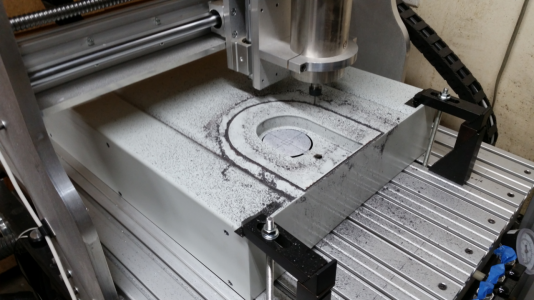

Mikini 1610L. About halfway between a 770 & 1100 Tormach in size. Linear rails & steppers (for now).I'm blanking on @spumco 's machine.

Mounting the encoder to the spindle is also tricky

Offset the encoder and drive it with a timing belt right off the spindle main pulley. Drive it at some sane ratio (1:1, 2:1, etc.) and adjust the PPR in the controller. This method has been used on plenty of lathes (Omniturn & other 'factory' retrofits).

Stolen off the 'net:

Determine your desired resolution needed for a spindle/C-axis (can't be that small, right?) and get one with a PPR that doesn't blow the optocouplers away on the BOB or drive.

A 1024 line encoder is 4096cpr in quad. So lets say a 5kRPM motor at 1:2 (for the magical 10k spindle) and a 2:1 reduction to the encoder.

4096cpr / 2 = 2048cpr at 10k spindle rpm.

2048 * 5000 /60 = 170khz. This is do-able most low-end BOBs which seem to all be using the same 200kHz optos.

And 2048cpr gives you 0.176 degrees per encoder count resolution. Not great for a 4th axis, but would be fine for a spindle to position a broach or line up for an ATC.

This also means you don't need to use a timing belt from the spindle motor to the spindle - any poly-V belt slip will be taken care of by the direct connection from spindle to encoder. Quieter belt drive at the expense of higher belt tension and top/motor bearing radial loads. You can get a cheapo USDigital, CUI, or import with whatever output style you want and not spend a fortune on a SICK or Heidenwhatever.

Most hollow-bore encoders I've seen top out at about 32-50mm bore - they aren't really suited to installation over a spindle.

-Ralph