- Joined

- Dec 3, 2013

- Messages

- 1,849

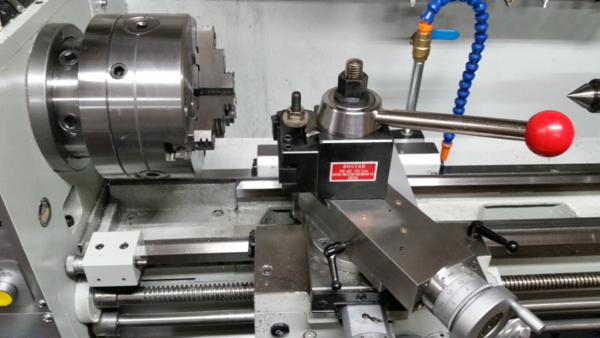

The BXA on the PM-1440GT has always felt a tad on the small size for this lathe. It works fine for 90% of what I do but I have been getting some larger jobs and have had the tool post shift a few times under heavy cuts.

I have been wanting to try a CXA size tool post and since I have another set of parts to do that caused me some problems before I figured this was a good time to try one. I didn't want to commit to the expense of a new Aloris or Dorian and the used ones seem to go for more that the new imports without any tool holders so I picked up a Bostar CXA set.

The CXA is 1/2" larger in length and width and 1/4" taller.

Here is an Aloris BXA holder next to the Bostar CXA.

The Bostar holder is marked XL and will hold a 1" tool. I"ll need to get a standard holder to compare. Looking at the Aloris catalog the standard holder has a slot for a 3/4" tool and the bottom shelf is 1/8" thicker.

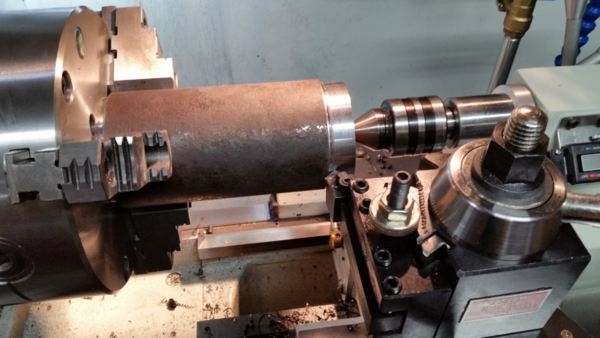

Here is the CXA mounted on the compound with a 3/4" tool. The tool is set on the center line and you can see there is still plenty of adjustment left. If the standard holder is 1/8" thicker at the bottom it will still be within the adjustment range.

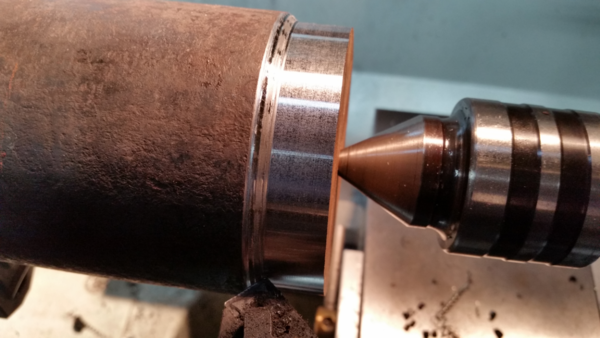

For a test cut I setup a 3-1/4" piece of A36 round rod. I took a .025 DOC cleanup pass followed by a .1 DOC roughing pass. 400 SFM (510 RPM) & .007 feed rate. It produced a nice stream of blue 9 shaped chips. That is about the max I will do in steel. Any deeper or faster I need to put on the fire suite to keep away from the blast of hot chips.

My first impressions of the Bostar are it is not quite the fit and finish of the Aloris (as expected) but at 1/4 the cost of the Aloris its pretty darn good. Very smooth out of the box and locks down good and tight. I do like that the t-nut is now full width of the compound and the contact area of the base is much larger.

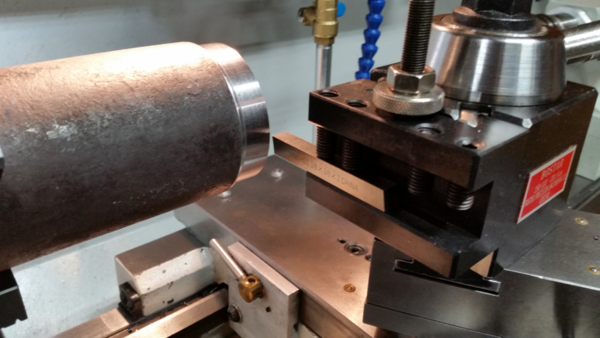

I did have to grind down the end of the handle where it threads into the body. It was too long and would tighten up against the center and keep it from turning. Once shortened up all works as intended.

The last photo here shows a 3/8" tool in the holder on center so this is about the smallest tool you can use without shimming.

So size wise, the CXA is a good fit. Maybe a tad overkill for most but I'm liking it so far.

I have been wanting to try a CXA size tool post and since I have another set of parts to do that caused me some problems before I figured this was a good time to try one. I didn't want to commit to the expense of a new Aloris or Dorian and the used ones seem to go for more that the new imports without any tool holders so I picked up a Bostar CXA set.

The CXA is 1/2" larger in length and width and 1/4" taller.

Here is an Aloris BXA holder next to the Bostar CXA.

The Bostar holder is marked XL and will hold a 1" tool. I"ll need to get a standard holder to compare. Looking at the Aloris catalog the standard holder has a slot for a 3/4" tool and the bottom shelf is 1/8" thicker.

Here is the CXA mounted on the compound with a 3/4" tool. The tool is set on the center line and you can see there is still plenty of adjustment left. If the standard holder is 1/8" thicker at the bottom it will still be within the adjustment range.

For a test cut I setup a 3-1/4" piece of A36 round rod. I took a .025 DOC cleanup pass followed by a .1 DOC roughing pass. 400 SFM (510 RPM) & .007 feed rate. It produced a nice stream of blue 9 shaped chips. That is about the max I will do in steel. Any deeper or faster I need to put on the fire suite to keep away from the blast of hot chips.

My first impressions of the Bostar are it is not quite the fit and finish of the Aloris (as expected) but at 1/4 the cost of the Aloris its pretty darn good. Very smooth out of the box and locks down good and tight. I do like that the t-nut is now full width of the compound and the contact area of the base is much larger.

I did have to grind down the end of the handle where it threads into the body. It was too long and would tighten up against the center and keep it from turning. Once shortened up all works as intended.

The last photo here shows a 3/8" tool in the holder on center so this is about the smallest tool you can use without shimming.

So size wise, the CXA is a good fit. Maybe a tad overkill for most but I'm liking it so far.