Karl, perhaps a final thought on cutting metric threads on your lathe with a QCGB.

As well as using gears such as 37-47 and 63-80 as spur gears to give a gear reduction that closely approximates to 1.27, the two gears can be mounted on a common shaft as a compound gear to give the magic 1.27 reduction.

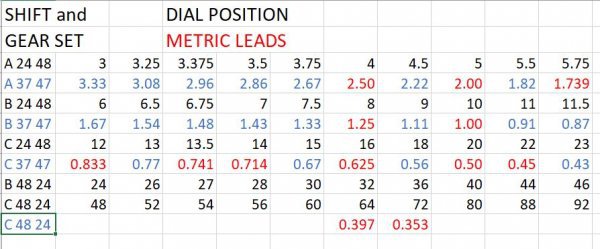

If you mount the compound cluster in your change gear set in the lower RH position (which looks adjustable), fit a 50 tooth gear in the bottom LH position, then mount one of 3 gears with teeth 60, 50 or 35 in the top position, then that should give you the following metric pitches (mm):

4, 3, 2.5, 2, 1.75, 1.5, 1.25, 1, 0.8, 0.75, 0.6, 0.5, 0.35

All with the accuracy of the compound set 80/63 or 47/37.

So, with a 60T gear mounted in the top change gear position, the following gearbox selector positions (ABC and TPI) give metric pitches of:

A+3 = 4mm, A+4 = 3mm, B+3 = 2mm, B+4 = 1.5mm, C+3 = 1mm, C+3 3/4 = 0.8mm, C+4 = 0.75mm and C+5 = 0.6mm

A 50T gear mounted in the top change gear position gives:

A+4 = 2.5mm, A+5 = 2mm, B+4 = 1.25mm, B+5 = 1mm and C+5 = 0.5mm

A 35T gear mounted in the top change gear position gives:

A+3 1/2 = 2mm, A+4 = 1.75mm, B+3 1/2= 1mm, B+5 = 0.7mm, C+3 1/2 = 0.5mm and C+5 = 0.35mm.

Regards, Ian