- Joined

- Jan 18, 2013

- Messages

- 34

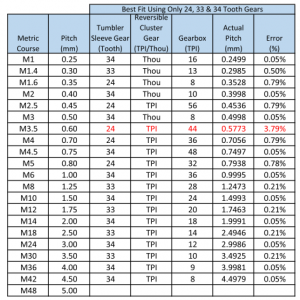

Recently I had a need to cut a metric thread on my old imperial lathe. Obviously the best way is to use a 127 tooth changegear, but a very good alternative is to use a 80/63 compound gear set, which approximates very closely to 1.27. Based on the use of a 80/63 compound gear and an 8TPI leadscrew I derived a threading chart.

Folks may find the thread chart below useful for selecting change gears when cutting metric threads on an imperial lathe. The driver gear is the output from the tumbler set. The second compound gear set with a ratio of 2 avoids the use of a 100 tooth gear driving the leadscrew and is optional.

Pitch O’all Comp Fract Driver Comp1 Comp2 Leadscrew

mm Red Red 1 Red 2 t t t t

0.7 4.5357 1.27 25/7 28 80/63 70/35 50

0.75 4.2333 1.27 10/3 30 80/63 70/35 50

0.8 3.9688 1.27 25/8 32 80/63 70/35 50

1.0 3.1750 1.27 5/2 30 80/63 idler 75

1.25 2.5400 1.27 2/1 30 80/63 idler 60

1.5 2.1167 1.27 5/3 30 80/63 idler 50

1.75 1.8143 1.27 10/7 35 80/63 idler 50

2.0 1.5875 1.27 5/4 40 80/63 idler 50

2.5 1.2700 1.27 1/1 55 80/63 idler 55

3.0 1.0583 1.27 5/6 60 80/63 idler 50

P.S. I can see that when posted all the formatting is lost, but in edit it re-appears. Sorry.

Folks may find the thread chart below useful for selecting change gears when cutting metric threads on an imperial lathe. The driver gear is the output from the tumbler set. The second compound gear set with a ratio of 2 avoids the use of a 100 tooth gear driving the leadscrew and is optional.

Pitch O’all Comp Fract Driver Comp1 Comp2 Leadscrew

mm Red Red 1 Red 2 t t t t

0.7 4.5357 1.27 25/7 28 80/63 70/35 50

0.75 4.2333 1.27 10/3 30 80/63 70/35 50

0.8 3.9688 1.27 25/8 32 80/63 70/35 50

1.0 3.1750 1.27 5/2 30 80/63 idler 75

1.25 2.5400 1.27 2/1 30 80/63 idler 60

1.5 2.1167 1.27 5/3 30 80/63 idler 50

1.75 1.8143 1.27 10/7 35 80/63 idler 50

2.0 1.5875 1.27 5/4 40 80/63 idler 50

2.5 1.2700 1.27 1/1 55 80/63 idler 55

3.0 1.0583 1.27 5/6 60 80/63 idler 50

P.S. I can see that when posted all the formatting is lost, but in edit it re-appears. Sorry.