I've considered going in from the back side but need to give this more thought. It would limit the diameter I can part but I'm not sure how much. Worth investigating and trying for sure. Ultimately I think my Logan 200 is a little flimsy. It's perfect for most things I do but for serious production work I'd want to get something much more solid.

I think the next step is carbide inserts or perhaps cutting from the back.

Parting from the rear is the same as parting from the front, except that it works much, much better. You can part anything that fits on your lathe, provided your parting tool is long enough. The key problem is going to be mounting such a tool because it requires T-slots on the cross slide. There was a post recently that pointed to a company that sells rough castings so guys with older lathes can put a T-slotted slide on their lathes. Parting from the rear works so well that if I had issues I would seriously consider modding my cross slide.

I've used a rear mounted parting tool on my Sherline for well over a decade. True, some think its a toy and can't run with the big dogs but I've parted materials up to 1-1/2" over the cross slide at high speeds without a hitch, from brass to 4340. I typically run at speeds somewhere around 2-3 times normal turning speeds for the material without a catch, stutter or hint of chatter. I use only P-1-N tools on this lathe, which is 0.040" wide, and there is very little force required to feed the tool into the work. I don't even pay much attention to stick out because it isn't critical with a rear mounted tool. I don't lock my slides or adjust my gibs. (I went to this tool because this lathe chatters when parting from the front in harder materials. However, if I am careful with alignment I have parted 2" OD steel from the front with this lathe.)

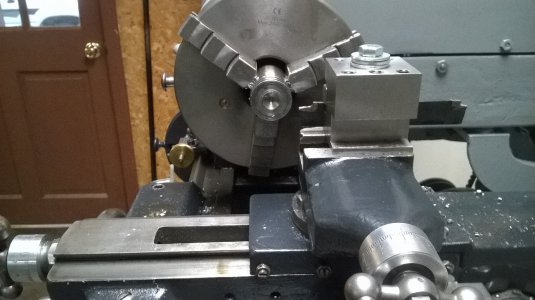

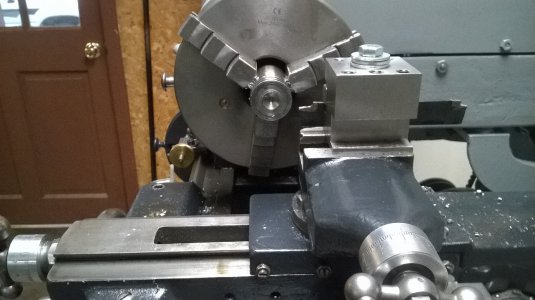

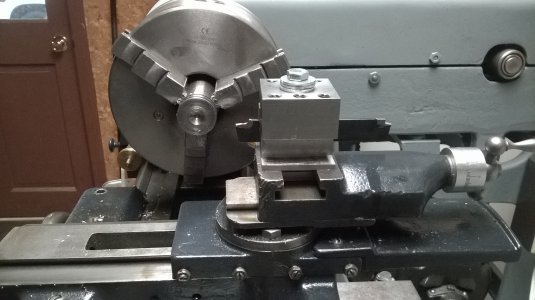

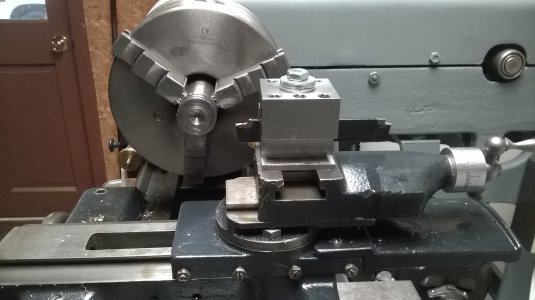

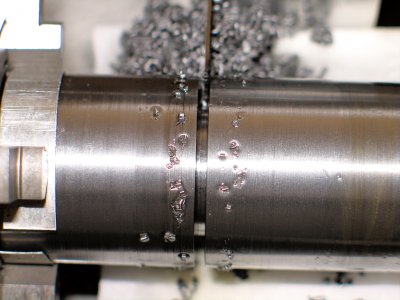

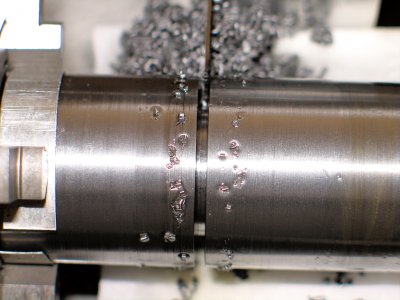

This is a groove being cut in mild steel at 1200 rpm. Note the stick out of the blade - still couldn't get it to chatter.

I also have an 11" lathe that parts from the front without any chatter so maybe this might help. I typically use a P-1 or P2 blade on it and very little feed force is required for it to cut cleanly at whatever turning speed I'm using. In contrast, parting with a GTN-3 blade does require more feed force but not a whole lot more if my turning speed is high enough. I like sharp tools but my parting tools seem to not be fussy about this; they get sharpened maybe once every few months (or more

).

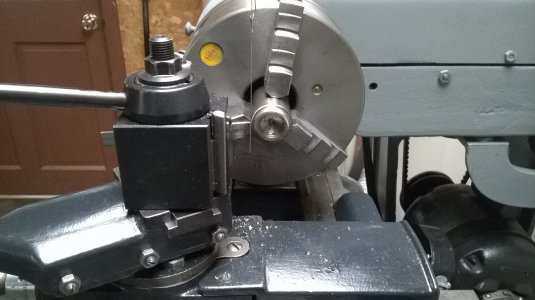

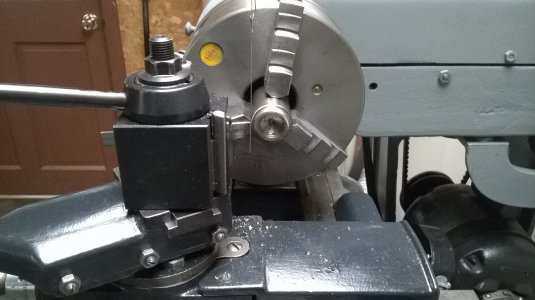

Parting from the front does require me to do some things. The tool has to be absolutely

vertical in the tool holder and then rigidly held. The tip has to be

on center; I check it with a tool,

not my eyeball. The blade has to be

perpendicular to the work; I align the blade on the face of the chuck because its handy. I prefer a 7-8 degree relief angle at the front of the tool; this allows it to cut cleanly without rubbing or sacrificing edge support. When parting from the front I do pay some attention to stickout but only casually. I typically do not lock anything and feed manually so I can feel the tool cutting. Again, very little force is used once it starts to cut and I maintain a constant positive feel as I go in. Finally, I relax. If I get tense I cannot feel the tool cutting and that affects the cut. Stupid? Maybe ...

I will admit that my Emco 11" lathe is in good shape and not worn excessively. If it were old and loose then things might be different. I have had this lathe chatter a few times. Typically, the tool is not on center or perpendicular to the work. Once I fix that I can get on with it.

Hope this helps.

).

).