- Joined

- Aug 23, 2014

- Messages

- 7

(I've access to a mini-lathe, mini-mill, and various hand tools.)

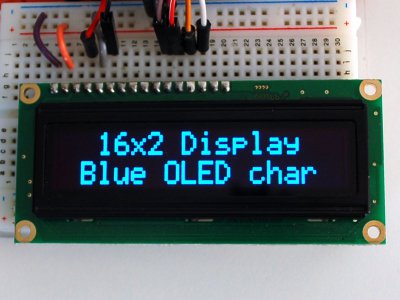

A square-ish piece of stainless steel, 2 mm thick, size about half a page. I need to cut a rectangular "window" in the middle of it - an LCD display will be fitted into that slot. The size of the display is about 70 x 16 mm.

One thing I could think of, and it would definitely work, is to use the machine and cut a slot with rounded corners. I've a 20-piece end mill set, 2- and 4-flutes, of various sizes. I could use one of the small mills, to minimize the radius of the corners.

Then grab a file and "sharpen" the corners until they're square. But it's going to be a slow process and probably won't look that great in the end.

Could anyone suggest a better idea? Thanks.

A square-ish piece of stainless steel, 2 mm thick, size about half a page. I need to cut a rectangular "window" in the middle of it - an LCD display will be fitted into that slot. The size of the display is about 70 x 16 mm.

One thing I could think of, and it would definitely work, is to use the machine and cut a slot with rounded corners. I've a 20-piece end mill set, 2- and 4-flutes, of various sizes. I could use one of the small mills, to minimize the radius of the corners.

Then grab a file and "sharpen" the corners until they're square. But it's going to be a slow process and probably won't look that great in the end.

Could anyone suggest a better idea? Thanks.