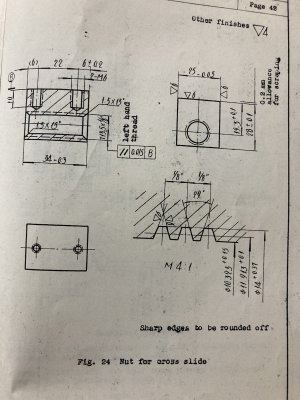

My interpretation is the 1.5x15 is a 1.5mm x 15 degree chamfer. The T13.5x1/8 is a 13.5mm (.531") diameter thread with a 1/8" lead which is 8 threads per inch. It must have either .125" or .250" dials depending on whether it reads off the radius or diameter. In metric, thread pitch is specified by the distance between threads. In imperial, we specify threads per inch. I've seen metric machines made this way in the past. Everything is metric expect for the pitch diameter which is imperial so they can have imperial reading dials.

If making both the screw and nut, you can pretty much, within reason of course, make the thread diameter whatever size you want. The important thing for a lead screw is the pitch (lead). Grind the tool to match an acme thread gauge for the desired pitch and match the nut with whatever diameter you select for the screw. I typically make the nut first and fit the screw to match for fit.

Ted