- Joined

- Dec 30, 2014

- Messages

- 259

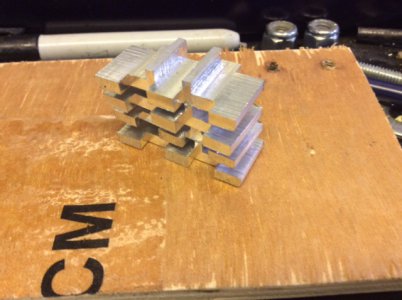

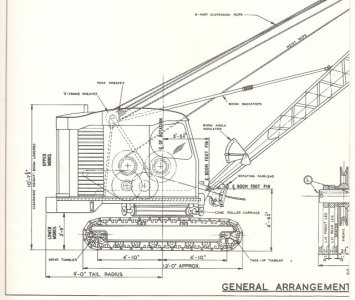

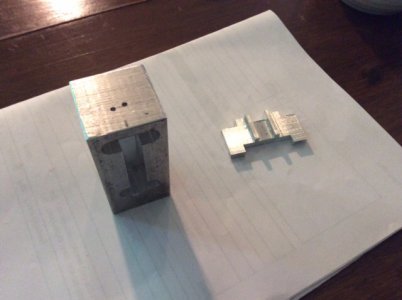

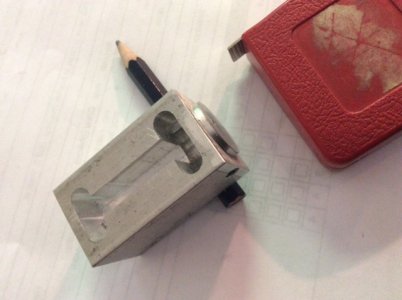

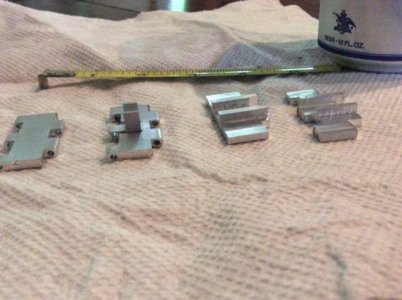

I am trying to make the track pads for a model crane undercarriage. What I have so far is pictured above. My question is how to proceed in a way to produce parts that are the same dimensions and will be sort of generic so that each pad will fit to any other pad. I started out with flat 1/8" thick bar stock and cut the sections to the rough length (or width actually). The pads are 1.5 x .5 and I am planning to use either piano wire or maybe brass rod to hinge them together. I have a few that are hinged as a prototype. What I found is I needed the cogs sticking up in the second from the left in order to drive the assembly. So, I decided to try using 1/4" thick stock and mill about the top half away leaving the slot down the center and eventually beveling the slot flanges so they will fold together as they round the wheels at each end. (Boy, this must be hard to follow...)

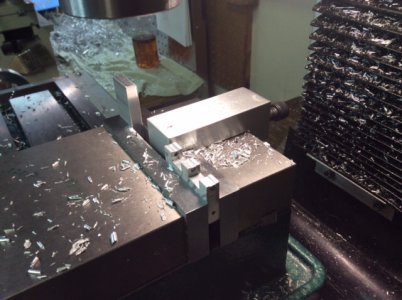

I also made a fixture block to hold a double stack of six each in the vice for milling. This seemed okay, but it seems like I still didn't get very repetitive results. I know this is all due to my inexperience.

But, when I decided to try the "three dimension" versions it seemed to complicate everything.

To simplify my question, would it be better/easier to mill the slot along 4 or 5 inches of the bar stock first, or, mill the overlapping fingers first, which would mean cutting the pads into individual pads first in order to make the finger notches on the leading and trailing edges of each pad?

I'm looking for any tips on what order or other ideas of how to produce the parts. I will need about 40 or so of these.

Thanks for looking, and if nothing else enjoy the pictures...

Jim