OK well that motor did not work out for me.

I did buy a new motor.

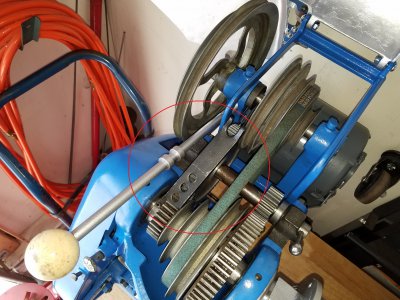

Century Motor 1/2HP 1725rpm 115V 60Hertz 1ph 6.8amps J56 frame. Shaft diameter 5/8" and 1 3/4" usable length. Includes shaft key. This motor is selective rotation, clockwise or counter clockwise. Condition is "New".

The body of the motor is approximately 9" long and 6 1/4" diameter. The shaft extends 1 7/8" from the motor body.

I will look into the pulley from Clausing.

Thank you!

I did buy a new motor.

Century Motor 1/2HP 1725rpm 115V 60Hertz 1ph 6.8amps J56 frame. Shaft diameter 5/8" and 1 3/4" usable length. Includes shaft key. This motor is selective rotation, clockwise or counter clockwise. Condition is "New".

The body of the motor is approximately 9" long and 6 1/4" diameter. The shaft extends 1 7/8" from the motor body.

I will look into the pulley from Clausing.

Thank you!

![20210814_170330[1].jpg](/data/attachments/332/332579-45cd58dc5c10fe094cf7a705945be4cb.jpg?hash=Rc1Y3FwQ_g)

![20210814_170348[1].jpg](/data/attachments/332/332580-e03b4fca370779127c4f81dbfe22c0af.jpg?hash=4DtPyjcHeR)

![20210814_170708[1].jpg](/data/attachments/332/332581-3ab4c8834fb9fe29f1eeb03612e27509.jpg?hash=OrTIg0-5_i)

![20210814_170437[1].jpg](/data/attachments/332/332583-b662b97193f4e97ca4cdd80a611d7c1e.jpg?hash=tmK5cZP06X)

![20210818_194441[1].jpg](/data/attachments/332/332944-64ba21765fd044d94066773c51b78968.jpg?hash=ZLohdl_QRN)