single phase 1/4 hp 110v motor. I have powered up the motor. I have not tried reverse.It could be that your setup is just using a ‘common’ switch for ‘forward’ and is not using the reverse at all.

Is it a single phase motor? 110v?

Have you powered it up yet? Does the reverse actually work?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Craftsman 101.21400

- Thread starter Blacksuit

- Start date

- Joined

- Apr 5, 2013

- Messages

- 391

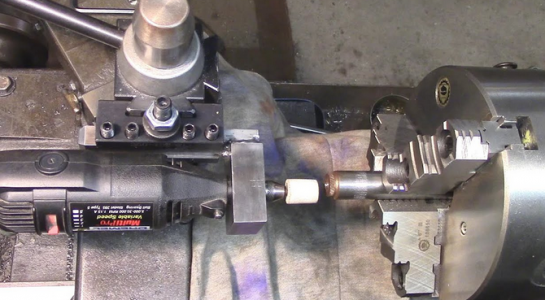

The milling attachment is fun , here is a post I did a few yrs ago https://www.hobby-machinist.com/threads/milling-attachment-for-a-6.94818/

If you have the room I would set one lathe up with the milling attachment and leave it like that .

On your bushing bearing lathe (101. 07301) is the cross slide a "V" thread or a Acme ?

If you have the room I would set one lathe up with the milling attachment and leave it like that .

On your bushing bearing lathe (101. 07301) is the cross slide a "V" thread or a Acme ?

cross slide a "V" thread or a Acme? I don't know. How can I tell?On your bushing bearing lathe (101. 07301) is the cross slide a "V" thread or a Acme ?

cross slide a "V" thread or a Acme? I don't know. How can I tell?

Crank the cross slide out of your way enough one way or the other that you can get a good look at it. Look for flats at the top and bottom of the thread form. The lead screw on your lathe is an Acme thread. Standard hardware grade bolts are a "V" thread.

- Joined

- Apr 5, 2013

- Messages

- 391

No big deal "V" or square , it's just me geeking out about Craftsman 6" 101's . When Atlas was converting (new design mainly back gear) from the 101.07300 to the 101.07301 , the first year of the 01's they were still using 00's lead screws and they were a "V" thread . And double lead to boot .

Mark .

Mark .

- Joined

- Dec 25, 2011

- Messages

- 10,552

Whether or not an Atlas built 6" Craftsman lathe has the same threads as an Atlas badged 6" depends upon the Ssears model number and when it was made. The 101.07301 made from about 1938 to mid 1957 had 1"-8 spindle nose threads. All subsequent models had starting in mid-1957 had

1"-10 threads, same as the Atlas badged units. The very rare 101.07300 made for about a year had 3/4"-16 threads. I think.

1"-10 threads, same as the Atlas badged units. The very rare 101.07300 made for about a year had 3/4"-16 threads. I think.

I have two 6in Craftsman lathes. One made prior to 1957 with the 1"-8 threads and a second made after 1957 with the 1"-10 threads.Whether or not an Atlas built 6" Craftsman lathe has the same threads as an Atlas badged 6" depends upon the Ssears model number and when it was made. The 101.07301 made from about 1938 to mid 1957 had 1"-8 spindle nose threads. All subsequent models had starting in mid-1957 had

1"-10 threads, same as the Atlas badged units. The very rare 101.07300 made for about a year had 3/4"-16 threads. I think.

- Joined

- Dec 25, 2011

- Messages

- 10,552

Someone asked why you would want to run the lathe motor and spindle in reverse. The first would be using a tool-post grinder. I would classify this as safe to do as as it takes considerably more torque to to break the chuck threads loose than it does to finish nu-screwing the chuck for removal.

The second is any case where the carriage drive must remain engaged for the duration of the operation, such as most metric threading with an inch-based lead screw. When the pass is complete, you back the cutter out a few thou and reverse the motor to back the carriage out.

The third (mentioned by someone else here) is power tapping with the tap mounted in the headstock, But for that you use a 2Mt or 3MT collet instead of a chuck. And you would have to rig up some way to hold the work piece.

And the fourth would be power tapping with the tap mounted in the tailstock,

The second is any case where the carriage drive must remain engaged for the duration of the operation, such as most metric threading with an inch-based lead screw. When the pass is complete, you back the cutter out a few thou and reverse the motor to back the carriage out.

The third (mentioned by someone else here) is power tapping with the tap mounted in the headstock, But for that you use a 2Mt or 3MT collet instead of a chuck. And you would have to rig up some way to hold the work piece.

And the fourth would be power tapping with the tap mounted in the tailstock,