Just an update-I bought this kit: http://littlemachineshop.com/products/product_view.php?ProductID=3786&category= which comes with cutters, the AXA QCTP, and also a chuck, some boring tools, and also some cutters. Hopefully this will be enough to get me started and I can buy more when needed as I identify those needs.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Couple Questions About My 9x20 Lathe

- Thread starter Kawabuggy

- Start date

- Joined

- Aug 22, 2012

- Messages

- 4,260

I have a set of those boring bars (they look like the generic chinese ones)

I had to hone the edges with a diamond hone to get a decent cut with no chatter.

Once I did that they cut ok.

(mine didnt come from LMS though so your milage may vary.)

I had to hone the edges with a diamond hone to get a decent cut with no chatter.

Once I did that they cut ok.

(mine didnt come from LMS though so your milage may vary.)

- Joined

- Feb 17, 2013

- Messages

- 4,415

I'm glad to see that LMS is including the post mount (adapter) with the AXA! I wan't even available several years ago.Just an update-I bought this kit: http://littlemachineshop.com/products/product_view.php?ProductID=3786&category= which comes with cutters, the AXA QCTP, and also a chuck, some boring tools, and also some cutters. Hopefully this will be enough to get me started and I can buy more when needed as I identify those needs.

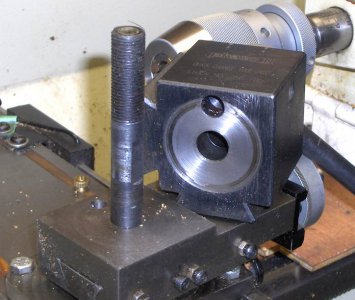

Once you have the AXA mounted on your lathe, check that it is held securely and doesn't spin. If it holds securely without undue force on the nut, you're golden! If it does have a tendency to spin, it's because the top of the compound isn't flat. It can sometimes bulge upward around the post (especially on a used unit like mine, where a previous owner has reefed down on the tool holder).

The fix:

(1a) If you have a piston-type base, remove the pistons and adjuster from the AXA body ... rotate the handle until one of the pistons is as far out as it will go. Clamp a pair of long-nosed Vise-Grip type pliers on the edges of the extended piston, so it won't retract. Turn the handle until the other piston is fully outward. The handle and barrel can now be lifted out. Unscrew the socket cap screws from the piston faces, and the inner pistons and springs can be removed.

(1b) If you have a wedge-type base, just unscrew the adjuster out the top and let the wedges fall out the bottom.

(2) Replace the original 4-way tool holder on the tool post. Mount the AXA base in the 4-jaw chuck, bottom outward, and "approximately" centered on the hole. Machine the bottom to a depth of .010" to .015", to within about 1/4" or 3/16" of the outside.

T

TOOLMASTER

Forum Guest

Register Today

- Joined

- Feb 17, 2013

- Messages

- 4,415

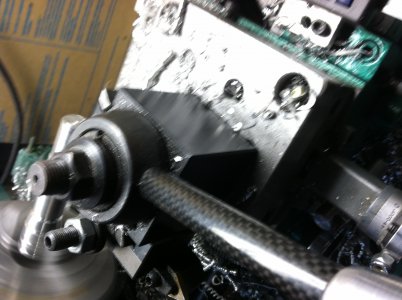

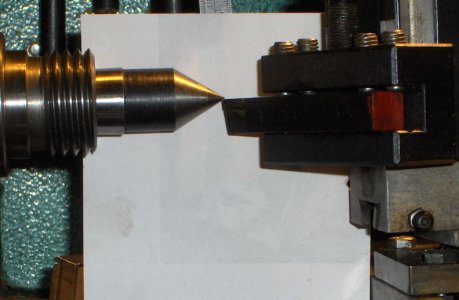

I've pur AXAs on two different vintages of Grizzly G4000 lathes with the "original" compounds. I did go to a 4-bolt mount, but that doesn't change the height.. Never had problem with ¼", 5/16", ⅜" or ½" tool bits. I think ⅝" would be a problem, but don't think the AXA tool holders are big enough anyway. The photo shows how a ½" tool bit lines up just below a headstock center.Hey guys. I'm a little confused about this thread. Will the AXA QCTP fit on the 9x20? Can you get the tool height low enough to be on center without modifying the compound? I thought that was a problem?

Robert

- Joined

- Aug 22, 2012

- Messages

- 4,260

yes but it obviously depends upon the thickness of the tool bit.Hey guys. I'm a little confused about this thread. Will the AXA QCTP fit on the 9x20? Can you get the tool height low enough to be on center without modifying the compound? I thought that was a problem?

Robert

On my lathe half inch tools can only be used with the AXA at 90 degrees to the compound or 45 degrees to the compound to allow the tool bit holder to drop that little bit further to get them on centre.

- Joined

- Mar 25, 2013

- Messages

- 5,107

Sounds like the AXA could be limiting. Would the OXO be the better choice? Could you not mill down the top of the compound to get the QTCP lower? Is there enough meat to do that? Oh yeah, I am only thinking aobut 1/2" tooling.

Toolmaster- Way cool with the carbon fiber!

R

Toolmaster- Way cool with the carbon fiber!

R

Last edited: