I will buy a pin gage set one day.

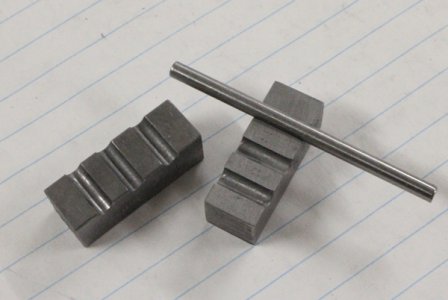

For fun, I ended up making four pins equal in both length and diameter: 1/4", 1/2", 3/4' and 1". My surface finish was an issue, but I got them to within about .0003". The surface finish was the limiting factor, and I am reluctant to use emery paper because the ways are brand spankin' new. It was good practice for turning to a diameter and facing to a length on my new lathe.

If I were to do it again, I would take down the last .0008"-.0010" with a smooth file or emery paper. I lapped one of two few faced ends, but I was in danger of going under the specified length.

Along the way, I realized that my DRO (on a PM-1030V) has a resolution of about .00020"; that is, the finest adjustment that I can dial to is .00020". So I am not able to dial in .0001" using the handwheel. I would have to use an indicator, and I don't have a test dial indicator with tenths graduations.

The 1/4" X 1/4" pin was really small in the 5" 3 jaw chuck. I don't think that I could chuck up a 1/8" X 1/8".

At one pojnt, I bumped the cross slide handwheel, dialed in for a finish cut and proceeded to scrap that pin. That scrap became the 1/2" pin. After that, I steered clear of the handwheels when measuring the part in the chuck (and kept track of my location on the DRO).

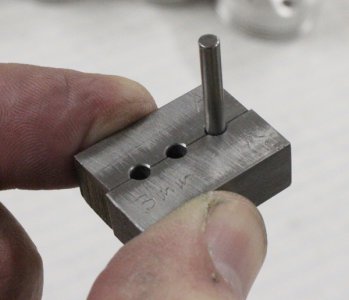

Here they are. These are the first things that I made with my first lathe.