- Joined

- Feb 25, 2021

- Messages

- 3,271

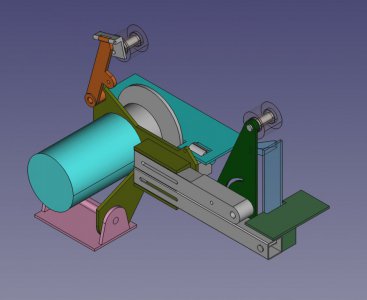

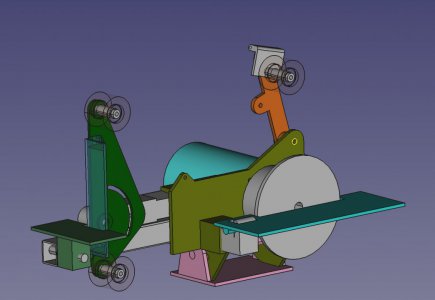

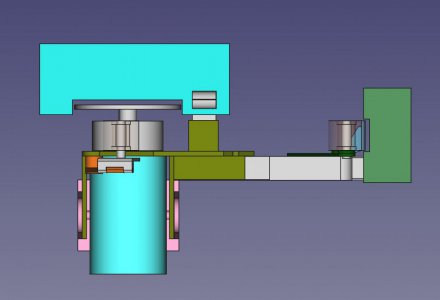

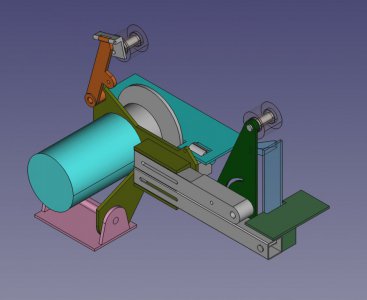

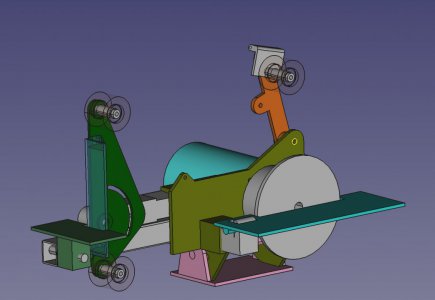

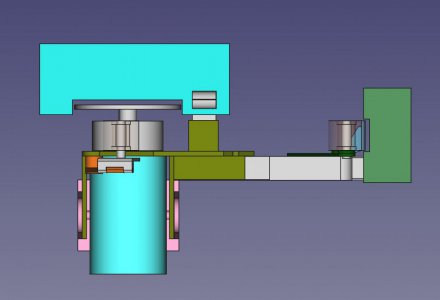

I've been fooling around with building a belt grinder, mostly muddling it over. Finally decided (New Years resolution) to use it as a project to teach myself FreeCad. I came up with the following idea, combining a belt grinder and disc sander. Maybe a boondoggle? Anyway, thoughts/comments from those who have built one before would be appreciated, on this and the general design issues. This is obviously not a polished design, but gets the proportions and general dimensions. Gas spring cylinder and some other basic hardware isn't shown. 9" disc. Base pivot with a 90 degree table turn on the belt grinder to give an edge sander.

Last edited: