- Joined

- Feb 20, 2013

- Messages

- 32

Hi, Im looking for suggestions for replacing the very wimpy spindle motor on my home built cnc mill.

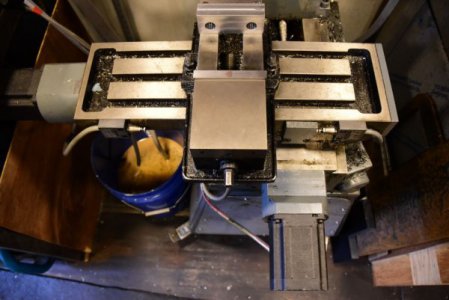

This converted mill was given to me a few years ago, its decently rigid and the person that built it put huge steppers on it. The spindle motor however is the original that came with the manual mill and is under powered, but worse, has a really low max RPMs. Details:

Original mill before conversion: ZAY7025FG

Spindle Motor: 370W, 1700 RPM induction motor

RPM options (H,L 1,2,3): 1700, 1120, 600 320, 220, 115

Conversion details:

C7 ballscrews on all axis

KL9082 Drivers

KL34H2120-60-4A Steppers (1200 Oz-In) on all axis

I use LinuxCNC as my controller. Ideally what I want in a replacement is spindle control (on, off, RPM), higher max RPMs (for better aluminum and plastic milling), more power for heavier cuts (I think the machine rigidity and steppers can handle it), and to completely bypass the gearbox of the spindle (it is loud and clunky and would be unnecessary if I had RPM control)

The simplest option would be to just upgrade to a higher power, 3400 rpm induction motor, it would be an easy swap and would get me at least more RPM and torque for heavier cuts.

But if im going to go to the effort, really I want full motor control, and ideally bypassing the gearbox.

What are my options. Is Odrive on a BLDC motor realistic?

This converted mill was given to me a few years ago, its decently rigid and the person that built it put huge steppers on it. The spindle motor however is the original that came with the manual mill and is under powered, but worse, has a really low max RPMs. Details:

Original mill before conversion: ZAY7025FG

Spindle Motor: 370W, 1700 RPM induction motor

RPM options (H,L 1,2,3): 1700, 1120, 600 320, 220, 115

Conversion details:

C7 ballscrews on all axis

KL9082 Drivers

KL34H2120-60-4A Steppers (1200 Oz-In) on all axis

I use LinuxCNC as my controller. Ideally what I want in a replacement is spindle control (on, off, RPM), higher max RPMs (for better aluminum and plastic milling), more power for heavier cuts (I think the machine rigidity and steppers can handle it), and to completely bypass the gearbox of the spindle (it is loud and clunky and would be unnecessary if I had RPM control)

The simplest option would be to just upgrade to a higher power, 3400 rpm induction motor, it would be an easy swap and would get me at least more RPM and torque for heavier cuts.

But if im going to go to the effort, really I want full motor control, and ideally bypassing the gearbox.

What are my options. Is Odrive on a BLDC motor realistic?