Yeah, I should give you more to go on.

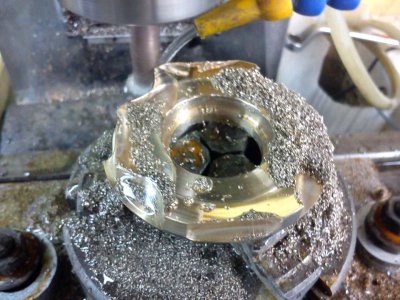

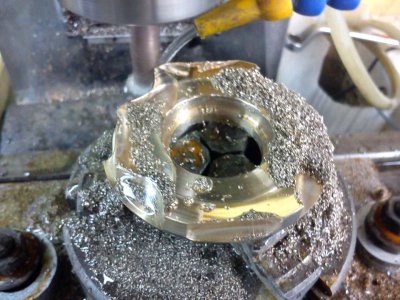

Material: Bronze (521)and Stainless Steel (316). Have a look at the pictures and you'll understand what I'm doing...

I need a chuck that I can place on my CNC. I may have to get creative since this is not mine.

- - - Updated - - -

Hi Tony, and thanks for your input. These are large case, solid metal, not delicate pocket watches that would be better machined on a Sherline. A four jaw may be best for the lathe, but for the cnc it wouldn't make much difference, it just needs to allow the tool to work around the work piece. I'm sure the pics will help some.

I may have to make something. I know there are some 5 and 6 inch table chucks that are out there, but their inner jaws are way too big to grip a 1 inch in diameter inside grip.

I can always clean up any small details later on the lathe too.

Your thoughts appreciated...

Just an opinion, not being a horologist, but I would think a small manual chuck with machined soft jaws would be best for a watch case. I believe the lack of precise grip pressure would work against a precisely round watch part.

- - - Updated - - -

As you can see from the pictures, the lathe is used to bore the inside hole, and the circumfrence of the what will be the crystal holder. The hole that is bored on the lathe is used on the CNC to hold the piece, and it is a three jaw (non-hydraulic) chuck. There is no hurry in machining these, so super strength isn't needed. A small end mill is used to chew away, and an even smaller one for clean-up. Hope this helps...