I also spoke this morning with Tech Support at All Machine Parts, Manufacturers of the Maxi Torque (really cool people). I wanted to get their thoughts and ascertain where I may have gone wrong, in an effort to mitigate future occurrence of the draw-bar stripped thread issue.

During the conversation and in honestly answering his many questions, I had to admit, maybe it was my fault because of my forgetting sometimes to send and lock the quill fully up before setting or ejecting a collet. This is something I will just have to get used to being constantly aware of and doing as standard operating procedure. He took his time, asked lots of pertinent questions and gave me good solid advice and pointers. Very nice folk to deal with, I am truly impressed.

Some pointers he touched on:

1) Quill fully retracted and locked when inserting or ejecting a collet

2) Item one above, you can get away with it if using smaller tooling, but certainly not anything over 1/2"

3) Collets and taper need to be clean and dry (acetone or some such), only the draw-bar threads need to have grease.

4) Never leave collets in the quill overnight (expansion and contraction), may cause jams.

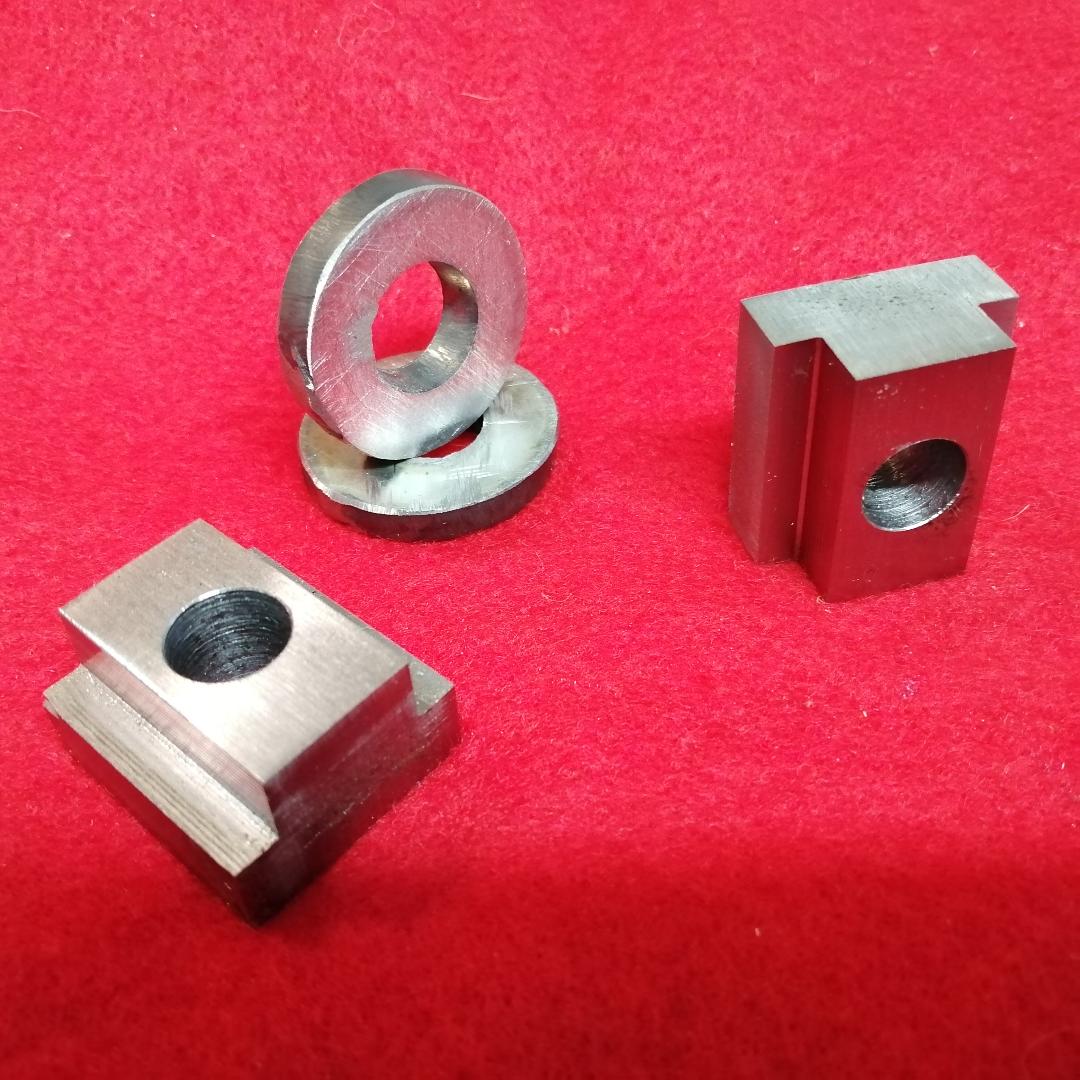

(Precision Matthews should consider branding and offering these in their product line).

(Precision Matthews should consider branding and offering these in their product line).