-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cleaning up an old milling machine

- Thread starter ML_Woy

- Start date

ML_Woy. That is a monster mill. How does every body keep their wives from freaking out when when you bring theses monsters home?

It takes great planning when handling delicate situations, first you start many months in advance of the delivery date. You mention how your development as a machinist is being hampered by the lack of the right equipment. Second, you talk about the price of new equipment and how expensive it is today. Then third you announce that you have miraculously been put onto a great find by one of our friends and it is something you have to act on right away or loose the opportunity. Fourth, have a long delivery date, so the damage to the family budget has time to season before the object arrives.

Sounds like a story doesn't it but actually it worked out that way. I found out about the mill in April, just before a huge federal income tax bill had to be paid, I was fortunate that the guy who sold it to me waited until September for me to take delivery and pay for it. It also helps to have a partner who has her passions and allows me to have mine.

In a week or so I am going to be posting the whole story on this project as to what transpired after the delivery and where it is now. So be looking for the thread update!

Thought I would drop an update on my PAL mill project. I have reached the point where the machine is now in operation and ready to make chips. The last couple of months, since I took possession of it in September, have taken me down a road I have never been before, working on a milling machine. When I purchased the machine I was understanding that it was only in need of some cleaning up and would be ready to use. Well after removing the sixty years of accumulated dirt I found out the real story. Seems this machine had suffered from not a lot of use but not a lot of first class repairs when any thing went wrong. Whomever had it before the owner I purchased it from took the approach of " Just do a quick fix and get back to work because time is money." The owner I purchased it from had no idea of how to operate the machine, how to lube it and consequently caused some expensive damage I later found.

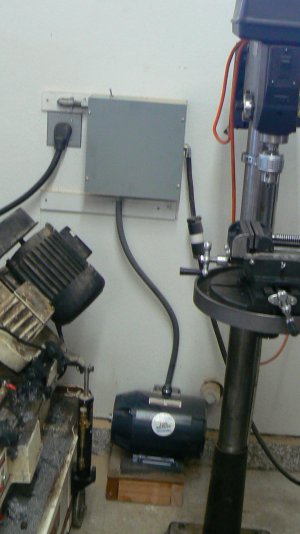

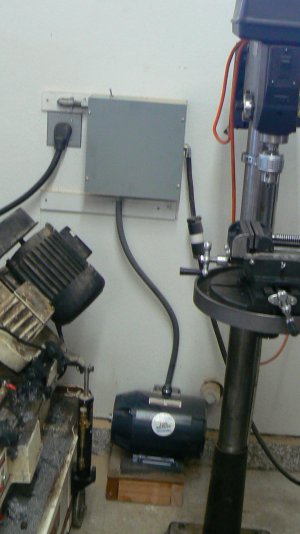

First thing I did when I got it unloaded was begin to remove the sixty years of old machine oil and cuttings glued everywhere on the machine. I quickly found parts missing and busted. Fortunately I have a retired friend who was a machinist and he came over and helped me carefully disassemble the gear boxes, and cross slide. I had been able to acquire some sales literature on the machine from Tony in England on the machine, but detailed data was totally missing. I found that the past owner had been lubing all of the way oil fittings with gear grease so all had to be removed and flushed so that oil would again flow to the way surfaces. The belts had to be replaced, requiring three trips to the parts house for the correct ones. Then the static phase converter, that came with the machine, was wired and mounted on the wall and I was ready to try and fire the machine. Well it started only to fill the room with smoke! Further investigations showed that the motor on the machine, a two speed motor,was not compatible with a static converter and the motor had been damaged by the prior owner. This required a new rotary phase converter and a rebuild of the motor. I was unable to find a supplier of two speed, three phase motors, from any of my local suppliers. I was fortunate to have a great electrical motor re builder here in Sacramento who repaired the motor. Good side, new motor and phase converter, bad side expensive! The project had suddenly doubled in cost. My original $1,200 purchase was now $2,300.

Only thing that saved me from my wife having a financial melt down over the project was that for many years when I was working I made it a point to throw all of my change from my pockets in a can every night for many years. When I retired and we moved to the country I had put the can out in the garage and forgot about it. Well while moving the mill around to get it into it's final resting place I stumbled across the can of coins. I decided it was time to take the can to the bank and cash it in, well it yielded $2,200 in currency when I exited the bank. The can paid for the repairs and enough money for a three axis DRO from DROPros.

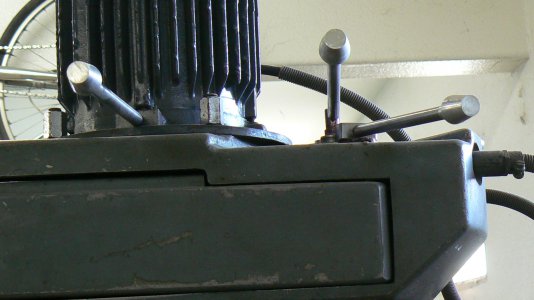

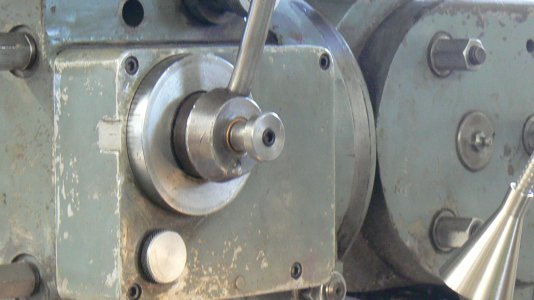

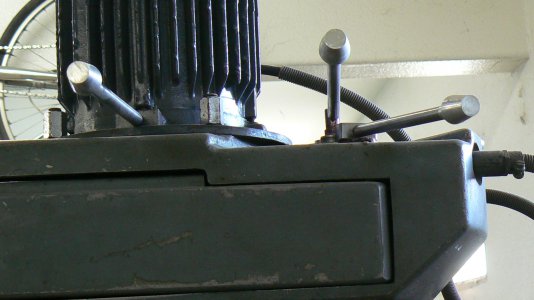

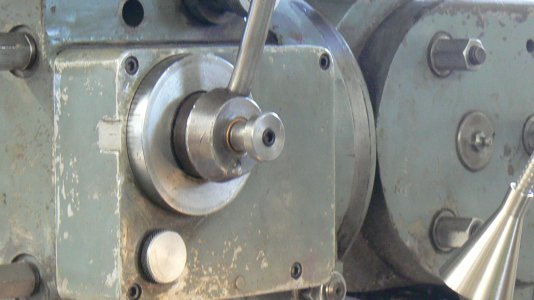

Today I finished mounting the DRO, all of the broken levers, knobs have been replaced and the machine is ready to use. Here are some pictures of how it turned out.

View attachment 95494

View attachment 95494

First thing I did when I got it unloaded was begin to remove the sixty years of old machine oil and cuttings glued everywhere on the machine. I quickly found parts missing and busted. Fortunately I have a retired friend who was a machinist and he came over and helped me carefully disassemble the gear boxes, and cross slide. I had been able to acquire some sales literature on the machine from Tony in England on the machine, but detailed data was totally missing. I found that the past owner had been lubing all of the way oil fittings with gear grease so all had to be removed and flushed so that oil would again flow to the way surfaces. The belts had to be replaced, requiring three trips to the parts house for the correct ones. Then the static phase converter, that came with the machine, was wired and mounted on the wall and I was ready to try and fire the machine. Well it started only to fill the room with smoke! Further investigations showed that the motor on the machine, a two speed motor,was not compatible with a static converter and the motor had been damaged by the prior owner. This required a new rotary phase converter and a rebuild of the motor. I was unable to find a supplier of two speed, three phase motors, from any of my local suppliers. I was fortunate to have a great electrical motor re builder here in Sacramento who repaired the motor. Good side, new motor and phase converter, bad side expensive! The project had suddenly doubled in cost. My original $1,200 purchase was now $2,300.

Only thing that saved me from my wife having a financial melt down over the project was that for many years when I was working I made it a point to throw all of my change from my pockets in a can every night for many years. When I retired and we moved to the country I had put the can out in the garage and forgot about it. Well while moving the mill around to get it into it's final resting place I stumbled across the can of coins. I decided it was time to take the can to the bank and cash it in, well it yielded $2,200 in currency when I exited the bank. The can paid for the repairs and enough money for a three axis DRO from DROPros.

Today I finished mounting the DRO, all of the broken levers, knobs have been replaced and the machine is ready to use. Here are some pictures of how it turned out.

View attachment 95494

View attachment 95494