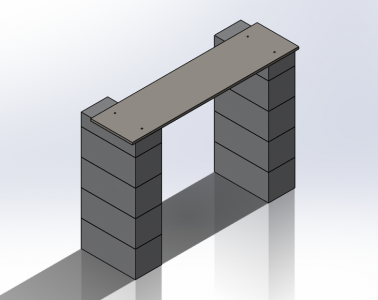

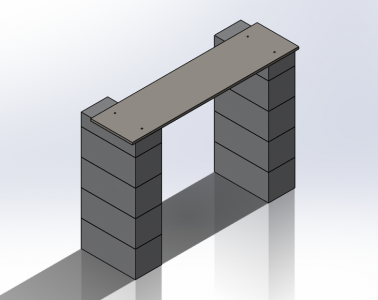

I decided I needed to just commit to something so I ordered and paid for the 5/8" steel plate. Here is a rough CAD drawing of how I plan to mount it. The rest of the materials should add up to well under $50, so I don't think I am going to blow my budget.

I decided to go with the solid cap blocks as AI 1 suggested, and to make life easier I decided to use the 16x8x8 blocks instead of the 16x10x8 blocks because 16x12x4 solid cap blocks are hard to find. I still think I am going to use PU adhesive instead of mortar, and I am just going to fill the pillars with sand to make my life even easier.

RE wood shrinkage: Finding exact numbers for plywood shrinkage is kind of difficult. Most of the woodworking sources imply that it it does not move at all, which for practical woodworking purposes might be true, but not for ours. Here are some numbers for solid white oak lumber. Between the green state (~28% moisture content) and the oven dry state (~8% moisture content), white oak shrinks about 0.2% lengthwise, about 5% width-wise is the tangential grain orientation, and about 10% width-wise in the radial grain orientation. This shrinkage occurs roughly linearly with moisture content, and seasonal change in moisture content of indoor furniture is in the 5%-10% range. Therefore, for solid timber you are looking at a several percent change in width over the season and maybe a 0.1% change in length. Plywood averages these changes due to its cross plies. As a low end number, lets say that a sheet of plywood will move 0.1% over the course of a season. In that case, you are looking at about a thou of movement per linear inch over the course of a season. The distance between the mounting holes for the feet of my lathe is ~37", so using those numbers a solid plywood top would give me about 37 thou of movement over the seasons. Obviously cast iron is much stiffer than wood and the lathe bed will resist that movement, but I really like the idea of having something like a steel top so that once I have everything in alignment it will pretty much stay that way unless I do something to tweak it.

Superburban - In retrospect, do you think you would prefer having the chip pan lower or right under the lathe bed? I have though about putting risers under the feet as well. Either way, I think I am going to use a cookie sheet or something as a removable chip pan that sits on the steel bench top.

Notgoingback - Thanks for the 43" reference point. This setup would put the feet at around 37" high, so I was worried it might be too tall, but that makes me feel better about it.

Thanks everyone for the warm welcome and all the suggestions! It is really helping me think this project through.

(edited to remove a random quote of myself that ended up in there somehow.)

I decided to go with the solid cap blocks as AI 1 suggested, and to make life easier I decided to use the 16x8x8 blocks instead of the 16x10x8 blocks because 16x12x4 solid cap blocks are hard to find. I still think I am going to use PU adhesive instead of mortar, and I am just going to fill the pillars with sand to make my life even easier.

RE wood shrinkage: Finding exact numbers for plywood shrinkage is kind of difficult. Most of the woodworking sources imply that it it does not move at all, which for practical woodworking purposes might be true, but not for ours. Here are some numbers for solid white oak lumber. Between the green state (~28% moisture content) and the oven dry state (~8% moisture content), white oak shrinks about 0.2% lengthwise, about 5% width-wise is the tangential grain orientation, and about 10% width-wise in the radial grain orientation. This shrinkage occurs roughly linearly with moisture content, and seasonal change in moisture content of indoor furniture is in the 5%-10% range. Therefore, for solid timber you are looking at a several percent change in width over the season and maybe a 0.1% change in length. Plywood averages these changes due to its cross plies. As a low end number, lets say that a sheet of plywood will move 0.1% over the course of a season. In that case, you are looking at about a thou of movement per linear inch over the course of a season. The distance between the mounting holes for the feet of my lathe is ~37", so using those numbers a solid plywood top would give me about 37 thou of movement over the seasons. Obviously cast iron is much stiffer than wood and the lathe bed will resist that movement, but I really like the idea of having something like a steel top so that once I have everything in alignment it will pretty much stay that way unless I do something to tweak it.

Superburban - In retrospect, do you think you would prefer having the chip pan lower or right under the lathe bed? I have though about putting risers under the feet as well. Either way, I think I am going to use a cookie sheet or something as a removable chip pan that sits on the steel bench top.

Notgoingback - Thanks for the 43" reference point. This setup would put the feet at around 37" high, so I was worried it might be too tall, but that makes me feel better about it.

Thanks everyone for the warm welcome and all the suggestions! It is really helping me think this project through.

(edited to remove a random quote of myself that ended up in there somehow.)

)

)