I agree with UlmaDoc and Mark - your tool is not sharp and the geometry is off, plus you're probably working with work hardened material.

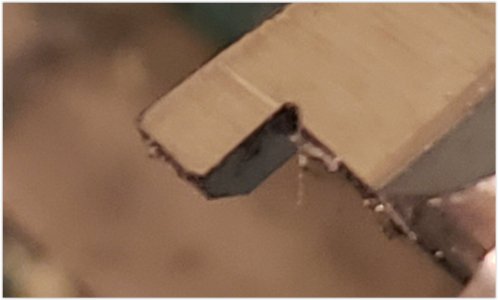

If you look at the tip of the tool, you can see that there is very little relief under the cutting edge. It looks like there is maybe a few degrees there but not enough. This will result in rubbing (no cutting) and heat build up with resultant work hardening.

View attachment 345761

The corners of the tool are also rounded and the cutting edge is crumbling. If this is a HSS tool then you can correct all of this easily. My suggestion is to grind a 7 degree relief under the cutting edge and clean up the sides so your corners are sharp, then hone the top flat.

I hope the work piece you showed in the picture is a practice piece because that chattered up section is going to be hard to cut through. With a good tool it is possible to cut through it. Bring the tool into contact and turn the work by hand, gently pushing the tool into the cut. A sharp tool will cut through the hardened layer this way. When you get through that layer the tool will begin to cut freely. At that point, you can turn on power.

If you are going to do this often, buy a solid carbide grooving tool from Micro 100 in the width you need. Forget inserted carbide for this job; the tip will just snap off.