Been chasing .003" of X axis backlash on my PM-932 CNC for four days now and haven't made any headway. Haven't checked the Y axis yet. It's time to tap into the Hobby-Machinist brain trust.

I've measured the backlash two ways. One method I used is to mount a .0005" DTI in the spindle and touch off on the vise. My other method is mounting a mag base with a 1" travel DI on the saddle, again touching off on the vise. I preload the dial indicator and set them to zero and also zero the Mach3 X axis DRO. I then jog the table in the opposite direction in .001" increments until the DI needle just begins to move and note the X axis DRO reading which is .003"-.004". For a comparison and to eliminate stick slip I tried the second method using a 1" travel indicator and jogged the table 1/2" and got the same backlash readings.

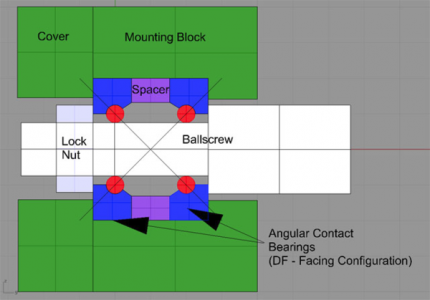

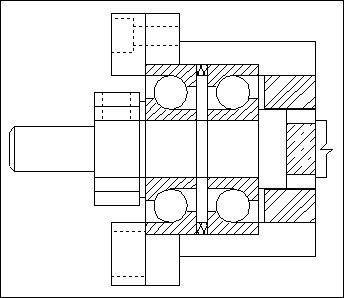

I've adjusted the gib several times and run the tests and no change in backlash except when I adjusted it too tight. I also adjusted the preload on the ball screw AC bearings. Having .003" to .004" of backlash I added .006" to the shim pack. Backlash is still .003" to .004". If I take shims out backlash increases.

Checked the ball screw for lateral movement with a DI and it's zero.

I installed Linear Motion Bearing double ball nuts a few months ago and was able to cut a pocket that was within .0005" of being round. Haven't tried this again so maybe it's time to retest.

What is considered acceptable backlash? Zero would be nice but I don't think it's a realistic expectation.

Am I checking backlash correctly? From what I've read on the internet I am.

Could it be bad AC bearings? These are the original Chinese bearings that came with the bearing blocks.

Could it be the coupling? I'm using split clamp style double diaphragm couplings with two set screws on each end. Although I don't like to run with rigid couplings, as a test I'm go to either make or buy one to eliminate that possibility.

Thanks in advance for your advice.

Tom S.

I've measured the backlash two ways. One method I used is to mount a .0005" DTI in the spindle and touch off on the vise. My other method is mounting a mag base with a 1" travel DI on the saddle, again touching off on the vise. I preload the dial indicator and set them to zero and also zero the Mach3 X axis DRO. I then jog the table in the opposite direction in .001" increments until the DI needle just begins to move and note the X axis DRO reading which is .003"-.004". For a comparison and to eliminate stick slip I tried the second method using a 1" travel indicator and jogged the table 1/2" and got the same backlash readings.

I've adjusted the gib several times and run the tests and no change in backlash except when I adjusted it too tight. I also adjusted the preload on the ball screw AC bearings. Having .003" to .004" of backlash I added .006" to the shim pack. Backlash is still .003" to .004". If I take shims out backlash increases.

Checked the ball screw for lateral movement with a DI and it's zero.

I installed Linear Motion Bearing double ball nuts a few months ago and was able to cut a pocket that was within .0005" of being round. Haven't tried this again so maybe it's time to retest.

What is considered acceptable backlash? Zero would be nice but I don't think it's a realistic expectation.

Am I checking backlash correctly? From what I've read on the internet I am.

Could it be bad AC bearings? These are the original Chinese bearings that came with the bearing blocks.

Could it be the coupling? I'm using split clamp style double diaphragm couplings with two set screws on each end. Although I don't like to run with rigid couplings, as a test I'm go to either make or buy one to eliminate that possibility.

Thanks in advance for your advice.

Tom S.