- Joined

- Jan 25, 2022

- Messages

- 129

Continuing my new lathe education: Thought I try boring a deep hole in my sacrificial brass rod. Don't have a boring bar with HSS, but one with carbide insert with those molded-in chip breakers. Thought I'd try it, not expecting great results.

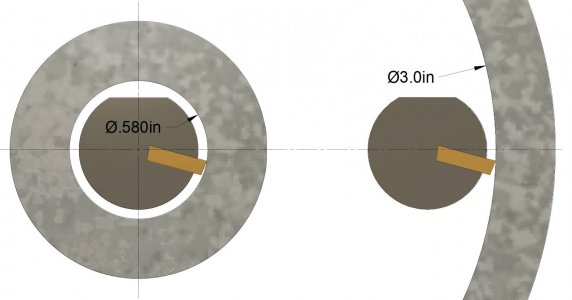

First drilled out to 0.5", about 1.75" deep, then bored to ~0.69". Didn't want to go larger as the walls were getting thin.

I was surprised at the results, thinking that tool geometry vs. brass would be a problem. Good finish all the way in (didn't check ID all the way in, however).

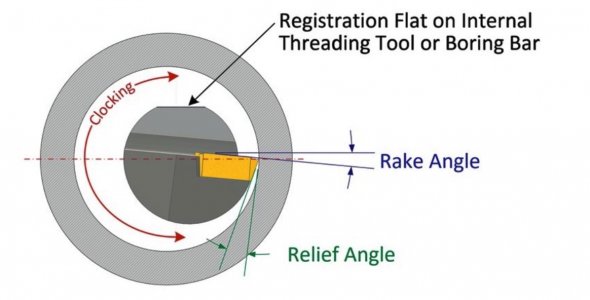

The carbide bit is rotated down about 20 degrees. Maybe that helped?

First drilled out to 0.5", about 1.75" deep, then bored to ~0.69". Didn't want to go larger as the walls were getting thin.

I was surprised at the results, thinking that tool geometry vs. brass would be a problem. Good finish all the way in (didn't check ID all the way in, however).

The carbide bit is rotated down about 20 degrees. Maybe that helped?