Stioc, you are right, I guess we are supposed to be the machine shop but those damn tool holders are really tough! I don’t own a surface grinder so I tried an end mill and made no progress, then I ground it down using a hand held grinder, it wasn’t pretty, so I dropped it off at a friend that has a machine shop with a grinder and he finished it off for me. I had him do a couple. The other is an inexpensive Chinese tool holder with a groove on the bottom that is intended for boring bars. I use that one to hold my dial indicator.

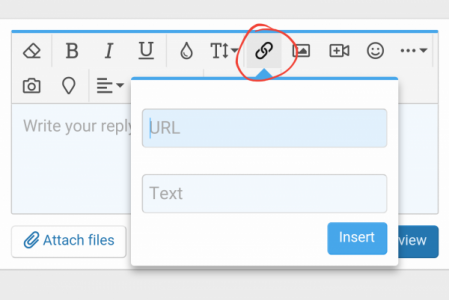

I like the 1236-T a lot, I am sure you will too! I would send you a link to a thread I have going on it here on H-M but not sure how to do it. I noticed some people put something like,”look here”and it links you to something but I haven’t figured that feature out yet.

Hope emergency call went OK

TK