- Joined

- Dec 20, 2021

- Messages

- 1,045

Lathe tools, gears, gear cutters, ect, ect. A gear cutter or boring bar only needs to be hard at the business end. I don't have any hard surfacing rod so to try it I'll have to spring for at least $40. It would be nice if I could find out if it would work before throwing money at this. Failing that, I'll have to go in blind. Thanks.

Edit: just noticed Nutfarmer responded with the same info!

You can weld tool steel onto steel. Have done that several times for a few odd projects. Have considered doing it more often. A company called Weld Mold, sells tool steel TIG rod. They also sell some varieties in MIG wire.

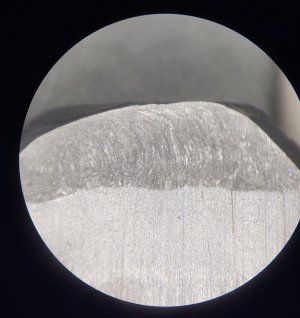

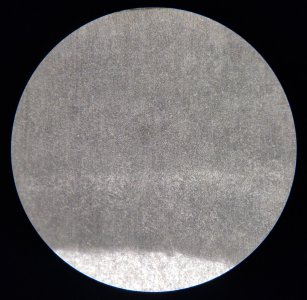

The trick (I think) is to use high alloy steels. Something like O1 is basically high carbon and has to cool very fast. Adding alloys tends to 'slow down' the steel (like an air quench steel), and these seem to harden fine when the weld cools. I did some tests with Weld Mold 958, and M2 drill bits. The 958 is similar to H13. Hardness testing the 958 gave ~58HRC, and the M2 drill bits were in the low 60s HRC.

Edit 2: Just found cut/etched images of the test slugs. 958 Middle, drill bits right. Much finer grain in from the drill bit, but you can see some weird layer near the middle bottom, guessing that's mixing from the base metal, but who knows.

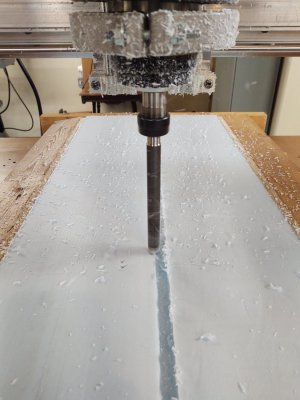

The two recent projects done in the shop here were for an unusually long ball end mill (I was being cheap!), and for a forming die. Also did a 'cup bit' for a guy who does woodwork a while back.

This is the ball end mill. It was done with 4130 round, and had with M2 TIG welded onto it. The trick source of M2 Tig Rod is old .040" and .0625" and .080" drill bits we discard at work. Similar material can also be purchased from Weld Mold and others (but the drill bits are free...).

In the case of the ball end mill, the business end was surface ground on the flat, and CNC milled with carbide to form the ball (with clearance angles set). Rough clearance was just hand ground. You can see it's not perfect, but the cutting edge was fine for what it was doing.

The die was just a sizing die for a part that was too small. rather than start over I grabbed a hunk-o-steel, milled, welded, and ground the die. Then just jammed it through the part. It formed it to size, or close enough.

In general, the whole process is doable. Advice would be to not spend too much time mixing the tool steel into the base metal. You want fusion, but not mixing. I believe several passes of tool steel build up would be recommended. Each layer gets less 'diluted' from previous layers.

Dan

Last edited: