I think you're right, sounds like a Mach3 issue. I don't have an answer for you.

Thanks for your help Jim. I'll load version 062 and see if that solves the problem.

Tom S.

I think you're right, sounds like a Mach3 issue. I don't have an answer for you.

I would start by getting a different version of mach3

.066 is junk so no matter what you should start there.

I'm using Version R3.043.057 without issue. the latter versions of mach3

were trying to fix lathe and the more they worked on lathe the worse mill got.

before installing an older version, make copies of your .xml files

after installing the earlier version, copy the .xml files you saved back into mach3 and you

will not have lost your settings.

uc100 may or may not have to be reinstalled, I can't remember

link to previous versions :

ftp://machsupport.com/Mach3/

Steve

Here you go. I couldn't upload the dxf file so I changed the extension to txt. You should be able to change it back to dxf and load it.

Tom S.

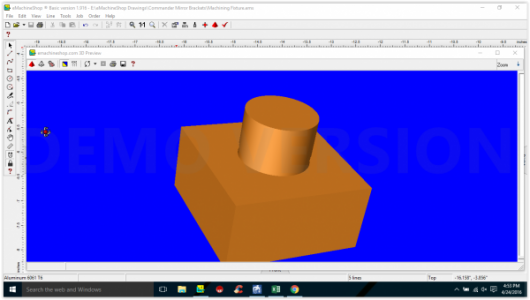

Is this what your part looks like? I get 0.0642 arc center offset (outside arc center to hole center), the hole center is offset to the left from the arc center. I wonder if the CAM program is picking up the wrong center?

View attachment 127687

I imported the dxf file in to my software and centered it in the work piece. The outside profile is centered but the center hole in off in X by -0.0321

These are the measurements returned by my software as I have seen issues with importing dxf files in the past I will post them here.

X 2.7002"

Y 3.156

Center diameter 2.01

If you wanted the center vector in the center of the piece than there is your problem if not then never mind.

Ray

Unfortunately that did not work.

I ran your code last night on a scrap of MDF but without dimensions I cant say if the center circle is correctly placed in the X axis. It is round and centered in the Y axis. The measurements I get (roughly) are 0.55" between the flat outer edge and the circle edge and 0.6" from the radius outer edge to the circle edge. The circle is 1.73".

I figured out the tool size and the rest of the parameters from the G-code you posted.

Attached is G-code from your DXF and my CAM program, using a Mach3 post processor. Give it a try, but make an air cut before you try to make chips just to make sure it behaves.