- Joined

- Feb 2, 2013

- Messages

- 3,957

on this episode of how the 1/4-20 tap breaks,

today at work....

due to the original manufacturer design was for delrin, it easily breaks and renders the meat cutting saw useless.

i'm now reproducing a part for a meat saw out of 7075 aluminum.

i figured if they break that 7075, we got bigger problems.

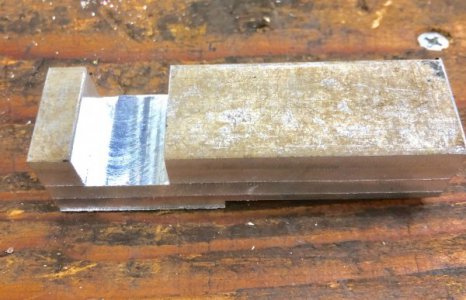

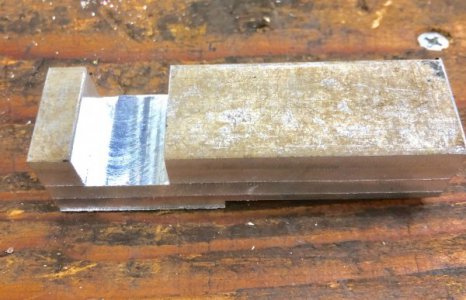

here is the 7075 in billet form, it is old and dirty, but there is a guide support hidden inside somewhere!

i had an example of a working model that i was able to reverse engineer and start chopping away at the billet...

here is my copy

the guide support emerges!

i felt really good, until i went to tap the last hole.

i have done 1/4-20 tapping in aluminum more times than i wanna remember,

but the problem this time was that i misplaced a drill bit when i filled the index

when i drilled the last hole, i only drilled to #13 (.185") rather than #7 (.201"),

that created a problem-

i broke the tap at about 3/8" engagement

do i scrap the part because of a broken tap at full depth????

Heck no!!!

i'm gonna save it, like an idiot!!!!

i took a couple 1/8" carbide ball endmills and turned the Bridgeport as fast as she could go.

luckily i was able to drill through the tap!!!!

then -

i, tried an old timer's trick...

i bought a small crock pot at the local walmart.

i filled the small crock pot with 32oz of Hydrogen Dioxide, and added the Alum.

when the mixture neared boiling point , i added the victim of my idiocy.

the alum goes to work quickly, especially in high concentration.

it is reminiscent of electrolytic rust removal, in that you actually see the reaction happening rapidly.

i'll see in the morning if the trick worked!

wish me luck!

stay tuned for part 2

today at work....

due to the original manufacturer design was for delrin, it easily breaks and renders the meat cutting saw useless.

i'm now reproducing a part for a meat saw out of 7075 aluminum.

i figured if they break that 7075, we got bigger problems.

here is the 7075 in billet form, it is old and dirty, but there is a guide support hidden inside somewhere!

i had an example of a working model that i was able to reverse engineer and start chopping away at the billet...

here is my copy

the guide support emerges!

i felt really good, until i went to tap the last hole.

i have done 1/4-20 tapping in aluminum more times than i wanna remember,

but the problem this time was that i misplaced a drill bit when i filled the index

when i drilled the last hole, i only drilled to #13 (.185") rather than #7 (.201"),

that created a problem-

i broke the tap at about 3/8" engagement

do i scrap the part because of a broken tap at full depth????

Heck no!!!

i'm gonna save it, like an idiot!!!!

i took a couple 1/8" carbide ball endmills and turned the Bridgeport as fast as she could go.

luckily i was able to drill through the tap!!!!

then -

i, tried an old timer's trick...

i bought a small crock pot at the local walmart.

i filled the small crock pot with 32oz of Hydrogen Dioxide, and added the Alum.

when the mixture neared boiling point , i added the victim of my idiocy.

the alum goes to work quickly, especially in high concentration.

it is reminiscent of electrolytic rust removal, in that you actually see the reaction happening rapidly.

i'll see in the morning if the trick worked!

wish me luck!

stay tuned for part 2

3 sets last night , 2 tonight .

3 sets last night , 2 tonight .