- Joined

- Feb 18, 2016

- Messages

- 451

I would like to extend a thank you to WarrenP for bringing up the clearance adjustment issue. This was something I really didn't think about it and could have potentially been a big issue. It just happens to turn out that I would have been ok just by pure dumb luck, but it's always good to check through these issues to be sure.

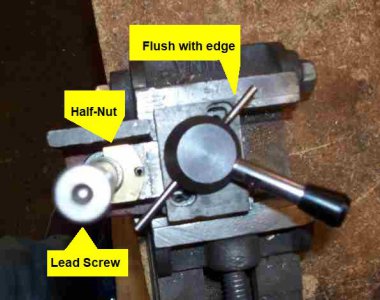

I put the half-nut lever back together and assembled the lead-screw, half-nut and lever together to check for clearance.

(see photo below)

It just happens to turn out that when the plate holding the half-nut level is precisely flush with the half-nut cage assembly it's at the perfect adjustment. This is exactly what I was planning on doing, but I really didn't think in advance whether this was indeed the right position. Now I can be certain that this will work perfectly.

As far as any fine adjustments are concerned I don't think there will be any need for that kind of precision. There is a spring-loaded ball detent that holds the half-nut lever in position. That ball detent is not the most precise mechanism, especially as manufactured in this case. The half-nut lever has wiggle room when locked in place by this ball detent. So the half-nut will actually be riding against the spring tension of the ball detent. This will give it room to move rather than bind should it happen to encounter a tight spot on the lead-screw.

I think it will be just fine if I anchor this plate flush with the side of the half-nut cage.

So I'm good to go. Now I can move forward to actually drilling and tapping the holes for the new bolts.

Thanks for bringing this to my attention WarrenP. It was worth looking into. In this particular case I would have been ok without checking, but things could have been different so it was well worth checking before committing.

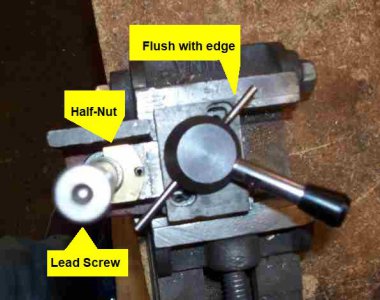

I put the half-nut lever back together and assembled the lead-screw, half-nut and lever together to check for clearance.

(see photo below)

It just happens to turn out that when the plate holding the half-nut level is precisely flush with the half-nut cage assembly it's at the perfect adjustment. This is exactly what I was planning on doing, but I really didn't think in advance whether this was indeed the right position. Now I can be certain that this will work perfectly.

As far as any fine adjustments are concerned I don't think there will be any need for that kind of precision. There is a spring-loaded ball detent that holds the half-nut lever in position. That ball detent is not the most precise mechanism, especially as manufactured in this case. The half-nut lever has wiggle room when locked in place by this ball detent. So the half-nut will actually be riding against the spring tension of the ball detent. This will give it room to move rather than bind should it happen to encounter a tight spot on the lead-screw.

I think it will be just fine if I anchor this plate flush with the side of the half-nut cage.

So I'm good to go. Now I can move forward to actually drilling and tapping the holes for the new bolts.

Thanks for bringing this to my attention WarrenP. It was worth looking into. In this particular case I would have been ok without checking, but things could have been different so it was well worth checking before committing.