I assume it only does it in high range. This is where the spindle is in direct drive with the front vari pulley via the meshing of teeth on the clutch (bottom is actually the big bull gear). All the clutch is, is teeth on the ends of the bull gear and vari speed pulleys. They mesh together and if not fully engaged will rattle and can be heard by turning the spindle back and forth by hand.

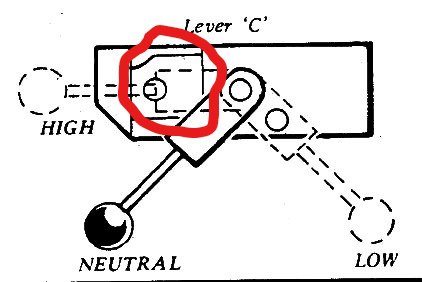

The hi/low lever is what is used to engage them. If this lever doesn't let the lower/big bull gear (which has the teeth on it) travel up far enough it will not fully engage and the mess will be loose. That handle, in the Hi position, needs to move up more to raise the bull gear more, to get more mesh.

Some machines have a sliding piece with the hi range hole in it and this can be moved up by loosening the set screw in the side. This piece can also be flipped upside down, if it hasn't been flipped before, to give more travel. The hole in it is slightly off center.

I hope this answers your question. Let me know if it's not clear.

Ted