What make and model? I do know that The TOS FNK 25 has 6 wires and ground going to the motor.

See link image below.

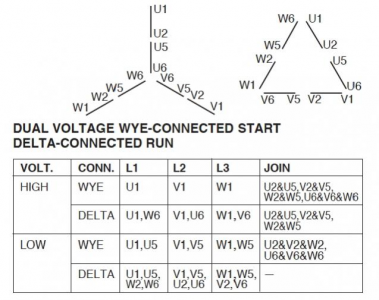

For WYE to delta speed.

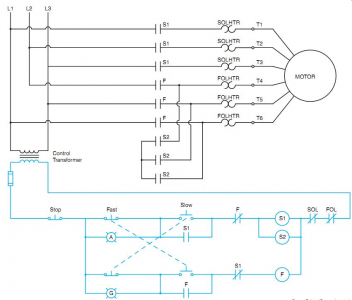

Leads 1 to 6 exit the control box.

Leads 1,2,3, are L1, L2, L3 and are live every time set to run.

leads 4,5,6 are to be joined to neutral only when set to WYE low speed on the control box. Then set to L1, L2, L3 on Delta high speed.

At the motor side, leads 1 to 6 are connected to the one below.

1 2 3 4 5 6 Join in a 12 lead motor. Ignore in 6 lead motor.

U1, V1, W1, U6 V6 W6 U2&U5, V2&V5, W2&W5

Low voltage

1 2 3 4 5 6 Join in a 12 lead motor. Ignore in 6 lead motor.

U1 V1 W1 U6 V6 W6 U2&U5, V2&V5, W2&W5

U5 V5 W5 U2 V2 W2

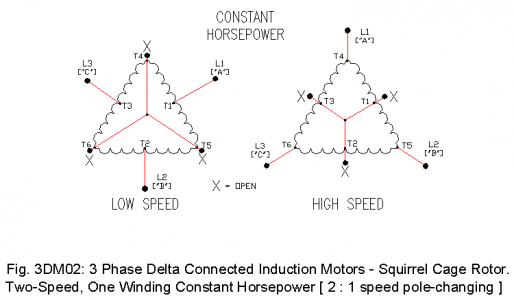

For High volt speed to low volt speed, first chose WYE to Delta for your top speed and input voltage.

WYE

Leads 1 to 6 exit the control box.

Leads 1,2,3, are L1, L2, L3, and leads 4,5,6 vacant when on slow.

Leads ,4,5,6 are L1, L2, L3, and 1,2,3, are joined.

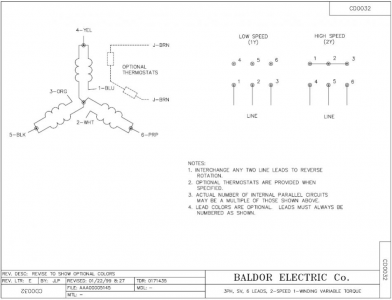

See last photo, your T1-T6 are your 1-6.

Delta

Leads 1 to 6 exit the control box.

Leads 1,2,3, are L1, L2, L3, and leads 4,5,6 vacant when on slow.

Leads 4,5,6 are L1, L2, L3, and 1,2,3, are L1, L2, L3,

1 2 3 4 5 6

U1 V1 W1 V5 U5 W5

W6 V6 U6 V2 U2 W2

Please someone double check me, I'm almost certain I have a mistake here, this is just a reference to inspire further reading. And for everyone stumbling across this be sure to disconnect your power before working. Branch all your U's V's and W's and check that leads 1 to 6 go to terminals that have at least have coil resistance corresponding to normal running speed or higher ohm's. Ensure that you are not putting top running voltage in Delta and LOW as to over heat, also not to put bottom running voltage High WYE as to run so slow it doesn't have the fan run fast enough to cool and likely stall.

View attachment 344949

View attachment 344954

View attachment 344955

View attachment 344956