-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bevel straight edge

- Thread starter GT-6 Racer

- Start date

- Joined

- Feb 1, 2018

- Messages

- 1,867

You can go to YouTube and search Richard King Scraping and see several of my students movies. Stefan Gottswinter and NYC CNC have good ones on why you scrape. Jon Brooks one of HM member did 2 of the CA classes. Keith Rucker and Adam Booth and a few others. You can check out my forum above - King-Way Scraping Consultants and I write about rebuilding and scraping too.I know nothing about scraping beyond trying to make a good number of contact points in a plane. How does that work for a fine edge? The edge forms a line instead of a plane, so any deviation (or scrape) would mean the edge is not straight between those contact points. Make sense? I understand scraping the planar surfaces, I'm just curious on how that works when those planes come to an edge.

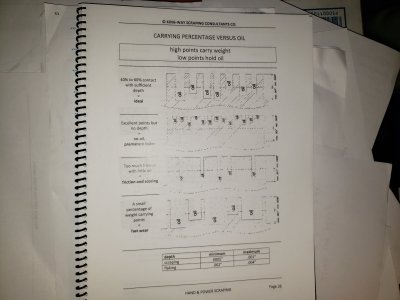

Below see some info out of my work booklet We want as many low places as high spot. On a straight-edge the more points 40 ppi (points per 1" is what we shoot for on a straight-edge, on most machines we try to get 20 PPI. The 2 right pictures are 50 PPI of my Austrian students straight-edges On picture 1 from left - most machines ways or straight edges would need to be scraped to the 3 from the left column. The 4th from left that is what we do to a "static" surface. Between the base and column that bolt together. We scrape 40 PPI and flat to .00005" in 12" .

We scrape them 40 PPI so they last longer as they are used. Column 1 from left is bad. It was what I saw in Taiwan before I taught there. low % means it wears out faster or the machines coming from Taiwan in the 1980s were called disposable. They ran good and accurate for a year and then the low % wore out and the machine wasn't accurate anymore.

Attachments

Last edited:

- Joined

- Feb 1, 2018

- Messages

- 1,867

If you want to check out another straight-edge maker is Gary Martin https://www.martinmodel.com/collections/machining-scraping-project-castings He has the prices on the different sizes - I recommend his.

- Joined

- Feb 1, 2018

- Messages

- 1,867

Yes and on the flats under the dovetails. A parallel or plane Camelback won't fit under there.I’m trying to understand , this bevel tool will be used to check dovetails on machines ?

- Joined

- Jun 7, 2019

- Messages

- 482

Denis is on Practical Machinist as dgfoster. I believe I got the casting directly from him. It’s been several years since I bought it.