- Joined

- Oct 7, 2020

- Messages

- 2,347

OK here is a monkey wrench for you.

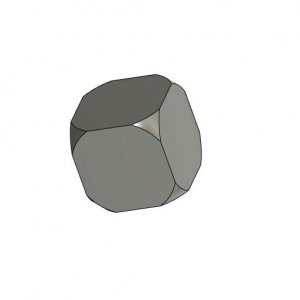

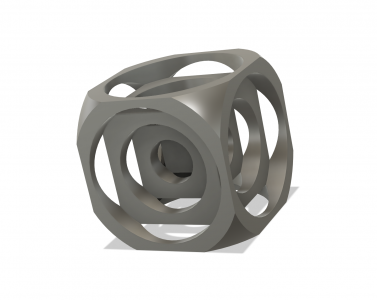

Since this is a "turners" cube, how about make the corners spherical?

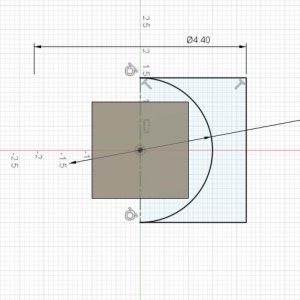

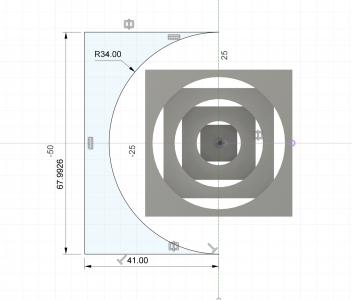

Both modeling and making would be easy. For modeling just use a sketch plane thru the center of the part draw the half arc to the center-line add 3 lines for the outside area and do a cutting revolve to knock off all the corners at the same time. To make just hit it with the ball turner. No ball turner, new project time...

If you want them flat just for modeling make a sketch plane rotated 45° from the center-line draw 4 triangles and do a symmetric cutting extrude. Create a second sketch plane 90° from that one and repeat.

Another way to get the sketch planes is to use 2 opposite edges to define the plane.

Another way is to pick 3 corner points.

Another way is to create an offset plane that is the distance needed for the flat of the corner to the center of the part. and extrude outward, but you would have to do this 8 times.

With everything in CAD I always say that there are at least a half dozen way to do everything and at least 3 of them will be good ways.

For your holder, in order to have something to dimension to I have been known to put a tiny feature in the 3D model so that I have something to dimension to. I am talking TINY like a feature they might only be 0.000001. You will never see it in the model or the drawing unless you are really zooming in on the spot. At most it will be 1 pixle on screen and one dodt as small as you printer can make on a printed page. but the software knows it is there and will let you dimension to it.

I'm not quite following you on spherical corners. What are the 3 lines for? I'm going to play with it in Fusion to see if I can catch up. I'll let you know how it goes.