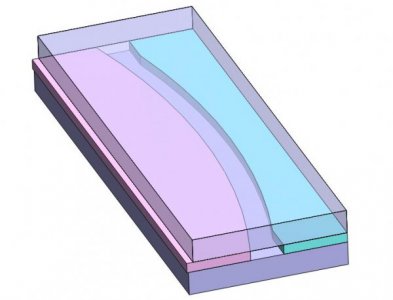

End result: RJ's method worked pretty well. The middle pieces -- with the arcs cut out -- needed to be thicker than shown, so clamping things to hold the half-round flat on the bottom piece while clamping required a little jiggering. To make the bend, I used a couple of pipe-clamps to provide the pressure, and had to really crank on them. Both the pink and the green pieces in RJ's picture ended up with considerable grooves in them -- like 3/32" deep -- but because I'd cut them with excess curvature in anticipation of spring-back, it all worked out.

I did, with a scrap, try the "just screw it down and bend it" approach. In an initial test, screwing it down to a test piece in about the position it would be on the real piece (i.e., near the edge), bending the other end inwards ended up splitting the wood (3/4 teak!). Secured better, in a beefier piece, the bending process deformed the half-round at the second screw-hole, where all the load was, and the rest of the half-round remained more or less straight. No doubt I misunderstood the instructions.

--John