- Joined

- Jan 5, 2014

- Messages

- 995

I'm looking for ideas on an upcoming project I have. I need to make a one-off for a customer and I'm a little stuck on something.

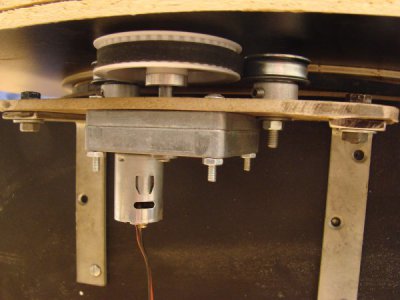

The project needs to servo-drive a large diameter platform, something like a 24" diameter lazy-susan. I need to turn it slowly, in one direction only, maybe up to 30 RPM at most. It needs to be fairly precise in the commanded angle. It needs to be very quiet and smooth when operating. I'm thinking about using a Type L timing belt and pulleys. I had considered gears but I think those might couple too much servo / gear noise to the platform. The pulley on the servo might be about 1.4" diameter, the smallest I can get. The platform pulley will be milled into the underside of the platform and will be about 16-18" diameter. This gives me a decent reduction ratio. The platform will either be plywood or plastic. Undecided.

With the speeds I'm thinking about I am wondering if I couldn't just purchase a timing belt, turn it inside out and glue it to the big pulley instead of having to mill 135 or more teeth precisely into the big pulley. Then I would run the actual timing belt over the top of that one. I know it doesn't mesh exactly but maybe it would work since the gaps are wider than the teeth and I only have to turn in one direction. The platform will weigh about 3-4 pounds including load and acceleration/deceleration can be kept very low.

Any pointers or ideas for the power transmission would be very helpful! Thank you.

The project needs to servo-drive a large diameter platform, something like a 24" diameter lazy-susan. I need to turn it slowly, in one direction only, maybe up to 30 RPM at most. It needs to be fairly precise in the commanded angle. It needs to be very quiet and smooth when operating. I'm thinking about using a Type L timing belt and pulleys. I had considered gears but I think those might couple too much servo / gear noise to the platform. The pulley on the servo might be about 1.4" diameter, the smallest I can get. The platform pulley will be milled into the underside of the platform and will be about 16-18" diameter. This gives me a decent reduction ratio. The platform will either be plywood or plastic. Undecided.

With the speeds I'm thinking about I am wondering if I couldn't just purchase a timing belt, turn it inside out and glue it to the big pulley instead of having to mill 135 or more teeth precisely into the big pulley. Then I would run the actual timing belt over the top of that one. I know it doesn't mesh exactly but maybe it would work since the gaps are wider than the teeth and I only have to turn in one direction. The platform will weigh about 3-4 pounds including load and acceleration/deceleration can be kept very low.

Any pointers or ideas for the power transmission would be very helpful! Thank you.