Every now and then I need to do something with sheet metal -- always stainless, because this is for a sailboat. I've got some stock in the basement -- some 0.075, 0.048, 0.06, 0.03 strip in various widths/lengths.

For today, I need to bend a 1" strip into an ell (one leg about 2", the other 1.5"), drill a couple of through-holes for #10 screws in the long leg, and drill a 5/8 hole in the short leg.

I can do the bending on a bender at work. I can drill the holes on a milling machine. I can clean up the holes with a countersink to de-burr the rough edges if I've got the terminology right.

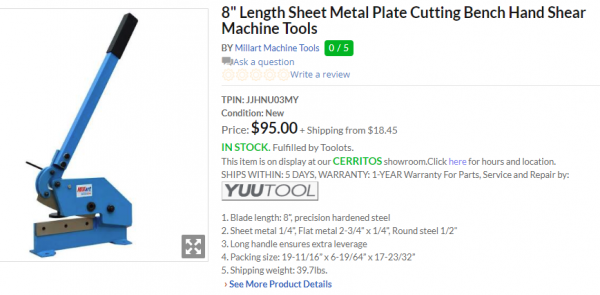

My problem comes earlier: I want to use the thicker material -- 0.075 -- for which I have a 2 x 24 piece. And that material is too thick to cut on the shear at work. So what's the best way to get 1"-wide stock with a nice fairly clean edge?

On a related note, when I work with thinner material, I can cut it with the shear, which is great...but when I try to drill a large hole in it, I often find the drill "grabbing" right at the end of the cut and mangling the edge of the hole, or otherwise messing up the material. I'm sure I'm doing something wrong here, but I don't know what. Any thoughts? And clever solutions for making holes in thin stainless stock?

Thanks in advance.

For today, I need to bend a 1" strip into an ell (one leg about 2", the other 1.5"), drill a couple of through-holes for #10 screws in the long leg, and drill a 5/8 hole in the short leg.

I can do the bending on a bender at work. I can drill the holes on a milling machine. I can clean up the holes with a countersink to de-burr the rough edges if I've got the terminology right.

My problem comes earlier: I want to use the thicker material -- 0.075 -- for which I have a 2 x 24 piece. And that material is too thick to cut on the shear at work. So what's the best way to get 1"-wide stock with a nice fairly clean edge?

On a related note, when I work with thinner material, I can cut it with the shear, which is great...but when I try to drill a large hole in it, I often find the drill "grabbing" right at the end of the cut and mangling the edge of the hole, or otherwise messing up the material. I'm sure I'm doing something wrong here, but I don't know what. Any thoughts? And clever solutions for making holes in thin stainless stock?

Thanks in advance.