- Joined

- Feb 2, 2013

- Messages

- 3,916

I had a motor on the bench this afternoon and thought it might be nice for those who have never seen the inside of a 3 phase 10 hp TEFC dual voltage motor.

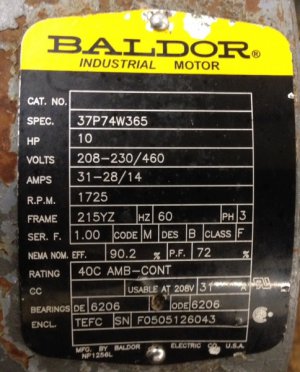

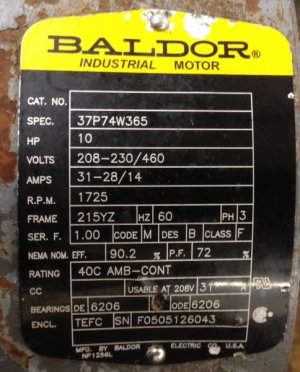

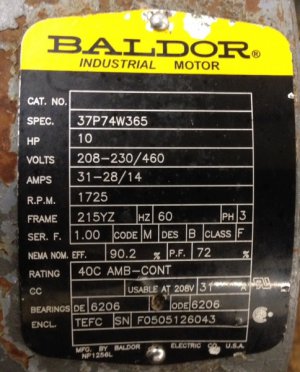

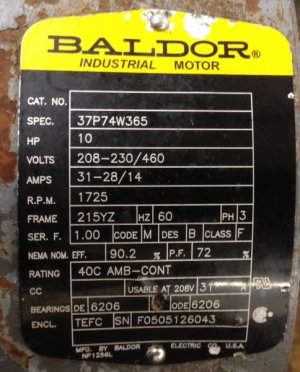

the victim is a Baldor 215YZ frame 10 HP 3 phase motor.

the motor did still run, but the bearings are no longer serviceable.

A bearingotomy and winding test will be the prescribed treatment, the cost would be a fraction of the cost of motor replacement.

this motor is a specification for Biro Meat Grinders,

and not available except through BIRO MFG.

Biro wants $2,800 for a new one....

NOT ON MY WATCH!!!!

here's the pictures.....

the motor tag

the side view, pre deconstruction.

the motor is Totally Enclosed Fan Cooled (TEFC)

here's the bi-directional fan. as the name implies, it will cool the 3 phase motor in forward or reverse rotation.

This is the fan end of the motor, the shaft stub is slightly visible behind the motor cage bolts.

this motor, like many electric motors, use long bolts or all-thread to cage the motor end caps.

this motor uses 5/16 -18 tpi x 18" bolts of caging purposes.

also seen is the foot mount as indicated by the YZ portion of the frame designation.

the motor is a standard 9 lead dual voltage TEFC 215 frame motor with fancy cast iron end caps with feet as specification for the BIRO motor.

i guess it gives them license to ask 3 times what a standard 215 frame motor would be...

the 9 lead winding is pictured below, no shorts were tested- resistance was low!!!

all good here!

Here's the shot of the end cap that houses the 6206RS C3 bearing.

they are identical end for end.

there was provision for seals too, in the specifications.

Here's a shot of the rotor assembly.

the bearing was rusted to the shaft and required the shop press for disassembly.

a curiosity was found during disassembly, one of the fins on the motor was severely bent out of position, as like as if something struck it during operation, there were a few faint scratches on other fins too indicative of an ooops moment for someone....

and the rotor sans bearings or superfluous housing...

Thanks for reading,

i hope the information may become useful to whomever may run across it.

comments and questions are always welcome.

the victim is a Baldor 215YZ frame 10 HP 3 phase motor.

the motor did still run, but the bearings are no longer serviceable.

A bearingotomy and winding test will be the prescribed treatment, the cost would be a fraction of the cost of motor replacement.

this motor is a specification for Biro Meat Grinders,

and not available except through BIRO MFG.

Biro wants $2,800 for a new one....

NOT ON MY WATCH!!!!

here's the pictures.....

the motor tag

the side view, pre deconstruction.

the motor is Totally Enclosed Fan Cooled (TEFC)

here's the bi-directional fan. as the name implies, it will cool the 3 phase motor in forward or reverse rotation.

This is the fan end of the motor, the shaft stub is slightly visible behind the motor cage bolts.

this motor, like many electric motors, use long bolts or all-thread to cage the motor end caps.

this motor uses 5/16 -18 tpi x 18" bolts of caging purposes.

also seen is the foot mount as indicated by the YZ portion of the frame designation.

the motor is a standard 9 lead dual voltage TEFC 215 frame motor with fancy cast iron end caps with feet as specification for the BIRO motor.

i guess it gives them license to ask 3 times what a standard 215 frame motor would be...

the 9 lead winding is pictured below, no shorts were tested- resistance was low!!!

all good here!

Here's the shot of the end cap that houses the 6206RS C3 bearing.

they are identical end for end.

there was provision for seals too, in the specifications.

Here's a shot of the rotor assembly.

the bearing was rusted to the shaft and required the shop press for disassembly.

a curiosity was found during disassembly, one of the fins on the motor was severely bent out of position, as like as if something struck it during operation, there were a few faint scratches on other fins too indicative of an ooops moment for someone....

and the rotor sans bearings or superfluous housing...

Thanks for reading,

i hope the information may become useful to whomever may run across it.

comments and questions are always welcome.

Last edited: