Sorry Tony! I should have looked closer at your profile!

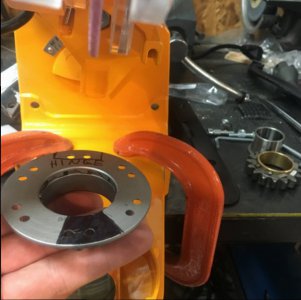

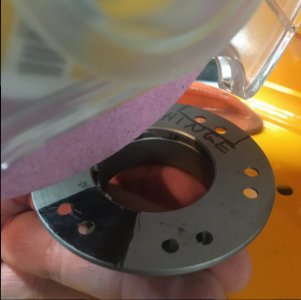

The slippage over time is due mainly to the wearing of the bushing that the spring loaded gear slides in and out on. Also, misalignment is compounded by another pair of thrust washers in the clutch hub. The teeth typically don't become misshapen and never do they shear off. The force upon these the gear and plate isn't monstrous I know they are hardened as a hand file is completely ineffective.

Thank you for the preface, I know my machine is a for the shade tree type like me. I did discover that this machine has rigidity issues especially after watching a real Bridgeport in operation.

You are correct that it wouldn't take more than a few degrees. The harder you push, the more they would lock together. It's also important that they release easily or there will be more serious trouble!

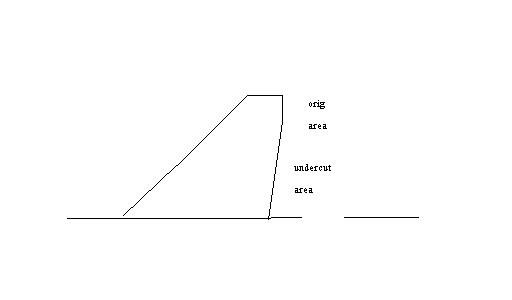

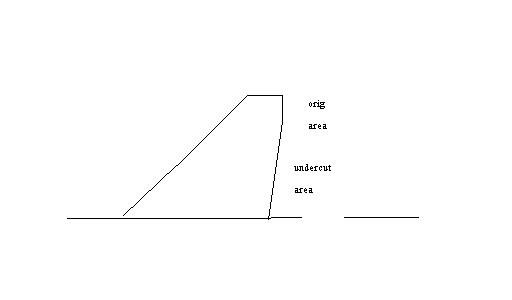

One gentleman suggested that the back cut start part way down the tooth face. This would leave some part of the original manufacture. Here is a quick drawing he did to illustrate.

I appreciate you guys putting some thought into this. Also, I was looking at this to do the cutting if a jig was made to hold each of the parts.

http://www.grizzly.com/products/Chain-Saw-Sharpener/T23108

The slippage over time is due mainly to the wearing of the bushing that the spring loaded gear slides in and out on. Also, misalignment is compounded by another pair of thrust washers in the clutch hub. The teeth typically don't become misshapen and never do they shear off. The force upon these the gear and plate isn't monstrous I know they are hardened as a hand file is completely ineffective.

Thank you for the preface, I know my machine is a for the shade tree type like me. I did discover that this machine has rigidity issues especially after watching a real Bridgeport in operation.

You are correct that it wouldn't take more than a few degrees. The harder you push, the more they would lock together. It's also important that they release easily or there will be more serious trouble!

One gentleman suggested that the back cut start part way down the tooth face. This would leave some part of the original manufacture. Here is a quick drawing he did to illustrate.

I appreciate you guys putting some thought into this. Also, I was looking at this to do the cutting if a jig was made to hold each of the parts.

http://www.grizzly.com/products/Chain-Saw-Sharpener/T23108