-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Atlas upper compound slide modification

- Thread starter iron man

- Start date

- Joined

- Dec 25, 2011

- Messages

- 10,552

Ray,

I don't know. The late (AKA Commercial) 12" part is about 5-5/8" long (not including the bearing plate) by 1-7/16" tall (to the machined flats for the tool post). This is tape measure and eyeball accuracy. Maybe someone with an early 12" will chime in. I don't have one available to measure.

Why would it have to be taller?

Robert D.

I don't know. The late (AKA Commercial) 12" part is about 5-5/8" long (not including the bearing plate) by 1-7/16" tall (to the machined flats for the tool post). This is tape measure and eyeball accuracy. Maybe someone with an early 12" will chime in. I don't have one available to measure.

Why would it have to be taller?

Robert D.

In recent photos I have seen of a craftsman commercial 12" lathe it almost appears by the photo like the upper cross slide is longer and taller it would almost have to be taller but longer? or is that just an optical illusion.. Ray

- Joined

- Feb 7, 2013

- Messages

- 792

Ray,

I don't know. The late (AKA Commercial) 12" part is about 5-5/8" long (not including the bearing plate) by 1-7/16" tall (to the machined flats for the tool post). This is tape measure and eyeball accuracy. Maybe someone with an early 12" will chime in. I don't have one available to measure.

Why would it have to be taller?

Robert D.

Just a thought the reason it would have to be taller is because the regular 12" compound is very tall. The commercial compound I only had to cut off 5/16" to make it the same height as the 10 inch compound so it would have to be taller at the slide or somewhere .. Which it appears to be it is also alot longer than the stock non-commercial slide or at least the 10 inch one that is only 4 1/4" long X 7/8 tall. I wish I had the commercial lathe obviously a better thought out machine. Ray

- Joined

- Sep 20, 2012

- Messages

- 560

That's the same cross slide as I have, and I had been thinking of doing exactly what's shown in that pic, but I wonder what compound and tool post it's intended for.

Using the standard compound that way means only using a small tool bit on the lowest adjustment with my QCTP, which makes it impractical for me, but it might just be OK with a lantern or some other type.

Bernard

I'm now thinking that it may have been made for mounting an Atlas milling attachment instead of a compound, so the height wouldn't matter at all..

Bernard

Edit, pic added

Last edited:

- Joined

- Jan 28, 2011

- Messages

- 3,584

The Atlas milling attachment actually mounted to the top swivel. I have a Palmgren milling attachment and it would mount onto the slide, not the top swivel. I did make up a base to fit the Palmgren to the top swivel as shown in this picture. I found that this setup was very flexible while with the milling attachment directly on the slide it was much more stable. It all comes down to surface area and fit of the dovetails for how stable anything mounted to the carriage will be.

Pierre

Pierre

- Joined

- Feb 7, 2013

- Messages

- 792

The Atlas milling attachment actually mounted to the top swivel. I have a Palmgren milling attachment and it would mount onto the slide, not the top swivel. I did make up a base to fit the Palmgren to the top swivel as shown in this picture. I found that this setup was very flexible while with the milling attachment directly on the slide it was much more stable. It all comes down to surface area and fit of the dovetails for how stable anything mounted to the carriage will be.

Pierre

I got one just like that one clever mount you got there. Ray

- Joined

- Jan 28, 2011

- Messages

- 3,584

Thanks Ray

You will note that the sub-base is some what thick. The reason I did this was to center the pivot bolt with the center of the spindle. This way the vice and the cutting forces would be better balanced. The piece was made from a broken punch press die parts. That is why there are extra holes. It was not too hard to cut, but on the Atlas it was easy as you go. No heavy cuts. The rabbet on the left was to locate the back edge of the Palmgren and the other cut on the right was to allow me to read to degree lines on the swivel.

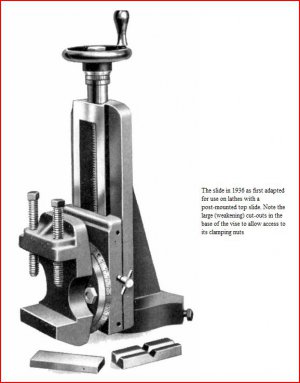

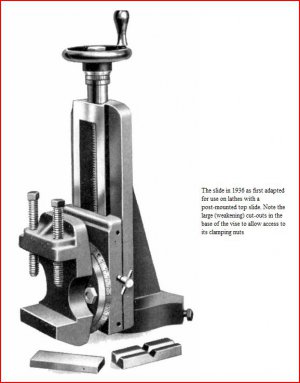

If you go ahead with making a new and longer lower sivel or even a new slide as shown earlier, the 9-671 Tool Post Slide, you will find that things will be much better than currently. The original slide is pretty short and with the longer slide that holds the full lenght of the dovetails, chatter is greatly reduced and the milling attachment will be much more stable as well. At least that was what I had found over the near 20 yrs that I had my Atlas. I really only used the regular top slide assy when cutting tapers and threads, otherwise the before mentioned Tool Post Slide was used for everything else.

Pierre

You will note that the sub-base is some what thick. The reason I did this was to center the pivot bolt with the center of the spindle. This way the vice and the cutting forces would be better balanced. The piece was made from a broken punch press die parts. That is why there are extra holes. It was not too hard to cut, but on the Atlas it was easy as you go. No heavy cuts. The rabbet on the left was to locate the back edge of the Palmgren and the other cut on the right was to allow me to read to degree lines on the swivel.

If you go ahead with making a new and longer lower sivel or even a new slide as shown earlier, the 9-671 Tool Post Slide, you will find that things will be much better than currently. The original slide is pretty short and with the longer slide that holds the full lenght of the dovetails, chatter is greatly reduced and the milling attachment will be much more stable as well. At least that was what I had found over the near 20 yrs that I had my Atlas. I really only used the regular top slide assy when cutting tapers and threads, otherwise the before mentioned Tool Post Slide was used for everything else.

Pierre

- Joined

- Dec 25, 2011

- Messages

- 10,552

Dunno why it wouldn't just show it. Maybe that only works with JPG's. Have to look into that.

Anyway, the PDF shows the long 9-671 cross slide as it was originally intended to be used as part of the No. 670 Carriage Turret on the 10" Atlas. The 12" is the same until sometime after 1958 except that the turret and tool post are taller and the rear tool post is square.

Robert D.

Anyway, the PDF shows the long 9-671 cross slide as it was originally intended to be used as part of the No. 670 Carriage Turret on the 10" Atlas. The 12" is the same until sometime after 1958 except that the turret and tool post are taller and the rear tool post is square.

Robert D.

Attachments

- Joined

- Feb 7, 2013

- Messages

- 792

Anyway I thought I would post an update I had to do some heavy boring for a friend of mine and I am amazed at the differance the new compound and upper compound slide have made!! Along with the QCTH I made it is one rock solid unit. I cannot wait to see what a new longer lower slide will do when I get that all made.. Ray