- Joined

- Sep 13, 2018

- Messages

- 283

Careful use of a transfer punch, followed by centre punch and then 2 sized drills will get you surprisingly close on a drill press. If you do end up using a vertical mill, then first draw up the hole patterns and create a x/y table for the hole poisitions. That lets you use the DRO or hand dials to accurate position for drilling/reaming.How could I add the bosses to the 5/8" plate? 5/8" plate is quite a bit more reasonable than 3" plate and mill it down to the boss surface.

Ideally I would think a vertical mill with a DRO would make quick work of this. I do not have access to one, but may be able to join a local Maker" for a month and "rent" one for $40. I am concerned that eyeing a drill press, even with the use of a wiggler would not be accurate enough.

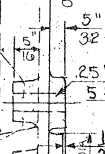

I suggest starting with 1/2" plate (changed my mind from 5/8"), then add in essence a washer as the 'boss'. In the snippet below, that washer/boss is 5/32". The 5/16" dimension is not as critical, it will only affect how long the shaft/bolt needs to be. The goal is to get the heights on rh side of that view to the same heights as original. Since they are shown as fractions, not decimals, precision in the height is not critical.

But, as suggested above by JPMacG, a good Plan B is to add a geared DC motor with speed control and do away with that gear train altogether. Its a bit noisy. The motor would let you dial in the feed rate while in operation, thus using the 'if it sounds happy then it must be good' method of determining feeds.

Gerrit