- Joined

- Dec 18, 2019

- Messages

- 7,430

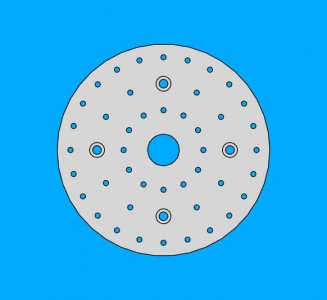

Just put my new Vertex HV-6 rotary table on the mill. If it is set to 0 degrees, should I have any expectation that the slots would run true to the mill table? They are rotated, about 3 degrees off. I have to rotate the table to 3 and about 18 minutes to indicate within a few thousandths. Is there a way to "calibrate" the table?

I know I can move the pointer a few degrees, but it isn't enough. I did try. Is there any other means to clock the table? The base (to stand up the table) is perpendicular to my mill table slots since I indicated it. Just checking if this is an ordinary angle offset, or not. It's not like they ship a beginners (new) user guide with these tables!

I know I can move the pointer a few degrees, but it isn't enough. I did try. Is there any other means to clock the table? The base (to stand up the table) is perpendicular to my mill table slots since I indicated it. Just checking if this is an ordinary angle offset, or not. It's not like they ship a beginners (new) user guide with these tables!