- Joined

- Mar 22, 2014

- Messages

- 869

Thanks guys!

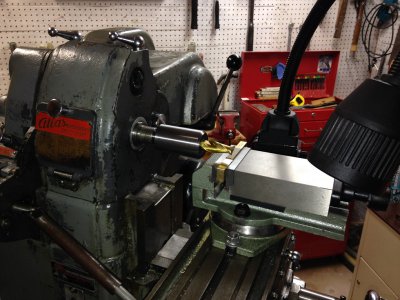

- Yes, this is with my Atlas MFC.

- I did take a spring cut.... no difference.

- The tip and the shank (beyond the flutes) both mic at .624. In between is about the same, although it is more difficult to position the mic.

- I checked movement in the X and Y directions with a dial indicator with its magnetic base stuck onto the head. X and Y are not bad: better than +/- .001 over about 3 inches of travel.

- Rolling the end mill on a counter top and sighting the edge, it does not appear to be bent. But this is not much of a test.

- I still need to check the Z movement. It might be that the jaws of my vise are not perpendicular to its base. It is a cheapo import from Little Machine Shop, but it fits the MFC nicely. Or it might be that the head casting is somehow misaligned.

- I do have some old American-made end mills. I will run one of those for comparison.

Last edited: