I'm already upside down according to your world view!

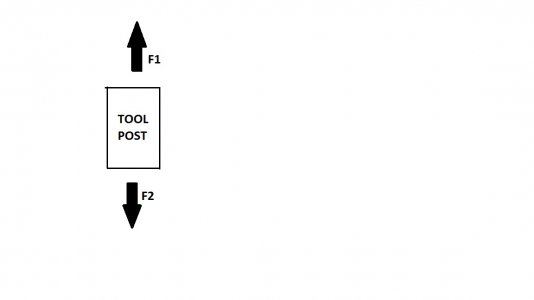

No, I keep my eyes open when parting and I usually sit down or stand on both feet facing the lathe. The reason I use an 'upside down' parting tool and run the chuck clockwise is that the chips or swarf falls down and it just works better. I part at nearly the same speed I turn at, fast and hassle free.

I was incorrect when I said I use a LH tool for boring though, I use a RH tool upside down from conventional cutting on the rear side of the lathe as it allows me to see what I am doing easier if I am doing something narly. If you ever have to bore out a track roller some genius has decided to blast weld into after a non-maintained bearing has collapsed and done so without removing all the broken bearing I can assure you that being able to observe the cut is pretty much vital.

I have never had any problem boring to size.